Big Data as one of the so called “digital enablers” of Industry 4.0 sits at the core of promising technologies to contribute to the revolution at factories where vast amounts of data (whether they are big or small) hides enormous amount of knowledge and potential improvements for the manufacturing processes.

The Strategic Research and Innovation Agenda (SRIA) of Big Data Value Association (BDVA) defines the overall goals, main technical and non-technical priorities, and a research and innovation roadmap for the European Public Private Partnership (PPP) on big data. Within the current expectations of the future Data Market in Europe (around 60 B€), Manufacturing was at the first place in 2016 (12.8 B€) and in the 2020 projections (17.3 B€), revealing a leading role played by this sector in the overall Data Economy.

With the aim to find an agreed synthesis, the BDVA adopted the “Smart Manufacturing Industry” concept definition (SMI), including the whole value chain gravitating around goods production, secondly identified three main Grand Scenarios aiming at representing all the different features of a SMI in Europe: Smart Factory, Smart Supply Chain and Smart Product Lifecycle.

Given the relevance of both Data Market and Manufacturing industry in Europe and in accordance with European initiative of Digitation of Industry, CARTIF, together with rest of experts from BDVA association engaged in a collective effort to define a position paper that proposes future research challenges for the manufacturing industry in the context of Big Data.

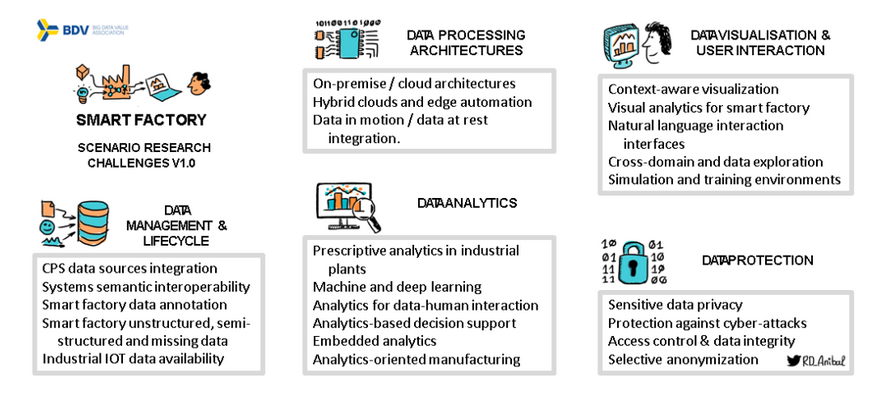

To contextualize these research challenges, the BDVA association has defined five technical areas for research and innovation within the BDVA community:

- Data Management and lifecycle motivated by the data explosion, where traditional means for data storage and data management are no longer able to cope with the size and speed of data delivered.

- Data Processing Architectures originated by fast development and adoption of Internet of Things (IoT) and the need to process immense amounts of sensor data streams.

- Data Analytics that aims to progress technologies and develop capabilities to turn Big Data into value, but also to make those approaches accessible to wider public.

- Data Protection addressing the need to ensure the correct use of the information whilst guarantying user privacy. It includes advanced data protection, privacy and anonymization technologies.

- Data Visualisation and User Interaction addressing the need for advanced means of visualization and user interaction capable to handle continuously increasing complexity and size of data and support the user exploring and understanding Big Data effectively.

During a series of workshops activities, started from the 2016 EBDVF Valencia Summit till the 2017 EBDVF Versailles Summit, BDVA experts distilled a set of research challenges for the three grand scenarios of smart manufacturing. These research challenges where mapped in the five technical priority areas of the big data reference model previously introduced.

To exemplify the outcomes of this mapping, the following figure gathers the headings of the set of challenges identified and discussed by the BDVA members into the Smart Factory Scenario. The interested readers are encouraged to analyze the full set of challenges in the SMI white paper.

Challenges set initially in this first version of SMI position paper set the tone for the upcoming research needs in different Big Data areas related with manufacturing. In the Smart Factory scenario the focus is on integration of multiples sources of data coming not only from the shop floor but also from the offices, traditionally separated in Industry 3.0. Interoperability of existing information systems and the challenge of integrating disruptive IoT technologies are major trials in the area of data management. Closer to the needs of a Smart Factory, the analytics challenges are focused on prescriptive analytics as tools for an optimal decision making process at the manufacturing operations management site including the optimization trough the evolved concept of digital twin.

- Behind the Curtain: Explainable Artificial Intelligence - 12 July 2024

- Digital Twin: Industry 4.0 in its digitised form - 9 October 2023

- Artificial Intelligence, an intelligence that needs non-artificial data - 16 December 2022