CAPRI, pathway and results

When a Project finalises, it is the time to recapitulate, time to collect all the information and the experience gained along. Along the three years and a half working in CAPRI project there has been a lot of time to do things, to obtain very good results or to feel bad because many times nothing seems to works well the first time.

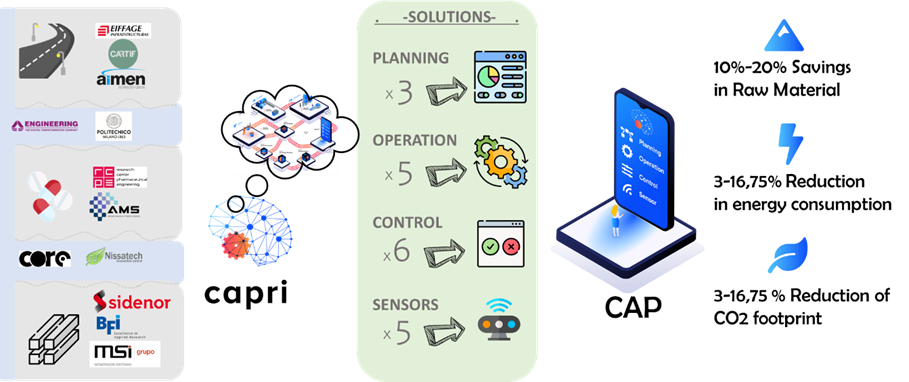

CAPRI project, has finalised in September 2023 and has achieved its main objectives defined during the beginning which were driven by the need of help in the digital transformation of the European process industry by investigating, developing and testing a cognitive automation platform. CAP, that integrates 19 different cognitive solutions defined in each one of the three project’s pilot plants. This platform has been designed to achieve the ultimate goal to obtain reductions of use of raw materials, energy consumption and CO2 footprint. With the finalization of the project, it can be shown that the reductions have been achieved thanks to the very close collaboration of the twelve partners involved, from seven different countries. The cognitive platform and solutions were deployed in three important sectors of the process industry: Asphalt manufacturing, billets and bars of Steel production and the production of tablets in the pharma industry.

For example, the asphalt pilot plant from EIFFAGE Infraestructuras, the cognitive solutions were related with the four automation levels, from sensors to planning, covering all of them.

The final prototype demonstrated under actual operation of the asphalt plant included very different technologies such as computer vision, vibration analysis, neural networks or mathematical models for parametrization of the existing data to predict the key performance indicators (specific energy consumption per tonne of asphalt mix or the final amount of raw materials used).

The cognitive solutions developed, like the cognitive control of the dryer drum or the new sensors, assures the quality of products and production in real time, reducing the used energy and raw materials. Before the project, the control of the materials used was based on estimations and now, with the mathematical model for mass balance and new sensors, the plant operators can receive an information in real time they didn’t have before.

The expected results of each Cognitive Solutions were defined during the first stages of the project to verify the improvements of each one during the validation period of the project.

CAPRI Project offers innovative solutions that have the potential to transform industries and drive progress. It highlights the project’s focus on unlocking new possibilities and empowering various sectors with cutting-edge advancements thanks to the generated key exploitable results.

Respect these results, inside the Asphalt use case, it has been included as exploitable results 3 solutions: a sensor to measure the dust aspirated online inside a pipe, the amount of bitumen present in recycled asphalt, and a predictive maintenance system of plant’s baghouse based on cognitive sensors and expert knowledge. The steel use case generated 2 exploitable results: a cognitive steel solidification sensor for continuous casting processes and a steel Product tracking. The pharma use case has 2 exploitable results: a cognitive sensor for granule quality and a quality attributes sensor.

The project generated also some transversal key exploitable results useful for any kind of industry: the technical architecture of the cognitive automation platform or CAP, and another one related to the open data generated, showing CAPRI project’s commitment with the open science the FAIR principles through the generation of more than 50 assets shared in open platforms, like Zenodo.

The main objectives of the proposal were the reduction of use of raw materials, energy and CO2 footprint. We can say with pride that we achieved those objectives as you can see in the summary table.

| KPI | After CAPRI |

|---|---|

| 5% – 20% Savings in Raw Material | 10-20% |

| 5% overall reduction in energy consumption | 3-16.75% |

| 5% reduction of CO2 foot print | 3-16.75% |

As an engineer, when a project finalises on time, and with these very good results, when your project has contributed to improve the industry, without damaging our environment, you feel better and all the sacrifices, extra hours and bad reviews was worth it.