The quality control of the products we consume daily is carried out by means of reference methods that present great limitations as to the necessity of sampling (which may or may not be representative of the whole), which also entails the manipulation and even destruction of the sample (which is a significant economic expense) and does not offer us an immediate response, which makes difficult taking decisions.

The agro-food industry continuously seeks solutions of quick, simple and direct application in order to improve quality and security controls of food, both in the final product and in the different phases of its production chain, starting with the variability in raw materials.

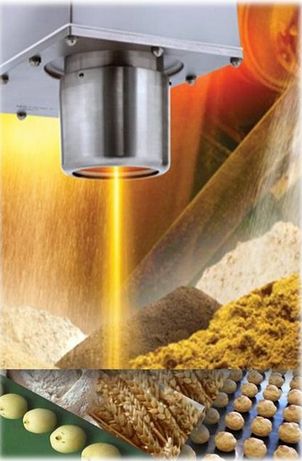

The spectroscopic (near-infrared) NIR technique alone or combined with hyperspectral imaging methods and using chemometric tools in both cases is a technology that saves the tedious, costly and long laboratory tests that the product usually requires to control its production.

NIR technology in online mode allows the monitoring of a process and product without interfering in it, to carry out a continuous and individual control of the production and continuously supervising the quality of the product, which facilitates an immediate adjustment if it would be necessary, contributing directly to the profitability of the plant.

It is true that this technique requires prior preparation of equipment with a significant associated cost, but in the medium term, it is compensated by the ease and the speed in the response to this need.

There are a lot of applications in which agro-food industry has applied online NIR in its labs, for last 15 years, but very few have implemented it directly on the production line, where its advantages are clearly evident.

What would it bring us?

With the information obtained from each product in real time and on the processing line itself, we would facilitate the taking of decision to ensure its quality and safety.

Where do we start?

Identifying the moment in which the product requires the control of some critical parameter that ensure its quality.

How do we do it?

Creating calibrations for each parameter at each point in the process that we want to control.

In CARTIF, we are sure of these advantages because we have been working with this technology for more than 15 years. We have used it frequently to support companies in the agro-food sector, starting with a diagnosis of the process to identify in what way, how and when it is most advantageous and necessary its application and developing the methodology to implement it in the company.

During these years, we have developed a wide variety of applications for very different products: from cereals to pulses, feed, eggs, dairy products, meats, cured meat products, etc., saving important challenges in terms of heterogeneity of products and the determination of minority compounds.

Currently, in CARTIF, we carry on working to companies make the most of this technology and we go on developing new interesting applications for industry and, definitively, for the consumer, such as the identification of contamination of food with potentially dangerous products for sensitive people, whether due to allergies or intolerances.

- NIRS: Let´s not talk about “new technologies” but about good applications - 16 February 2024

- What is an online NIR and what are its uses? - 7 March 2017