What if we had a tool that we could carry in our pocket and that would allow us to control the quality of the food products at any point in their production?

Dear sirs, we have it!! It seems like and advert selling a panacea,I know, but I´m not going beyond reality…. I´m talking about Near Infrared Spectroscopy technology, known as NIRS, which has been in our lives for more than 30 years and,at last, we are taking good aim at applying it in places and moments that can get us out of many predicaments in our day-to-day lives in the agri-food sector, so let’s give it the treatment it deserves!

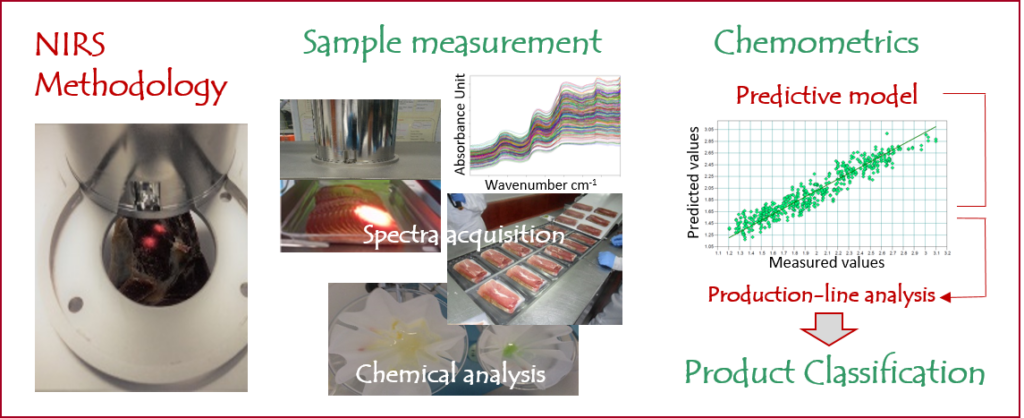

Well, being rigorous with this technology , near-infrared analysis is an instrumental technique in the field of molecular spectroscopy, wihich requires chemometric treatment of the data obtained, because the signal obtained in the near-infrared is so complex that the bands of the spectrum are difficult to interpret. And here we start with the complicated terms… chemometrics? Quite simply, statistical techniques to which you have to apply logic, good common sense and a lot of chemistry!!!!

The methodology followed using NIR spectroscopy leads us through analyses aimed at characterising products by quantifying analytical parameters that are of interest to us or that are critical for quality control of both raw materials and products during processing or of the final product.

In addition, another application of this technique is that it is capable of discriminating products according to the quality standards set by the company itself at each stage of processing. In this case, these are (non-targeted) classification models that allow you to identify or detect that something has changed in the product, which may be due to a change in the raw materials (differences in nutritional composition), changes between batches (which may affect the final product), production problems (dosage of ingredients) and even if there is any adulteration in any ingredient used or possible contamination in its preparation.

The verification of a production process generally depends on the results obtained in a laboratory through long and costly analytical methods, which implies “not-inmediate” response times. NIRS technology is an analytical tool that allows us to track the traceability at any point and along the entire production chain and, therefore, provides us with important advantages in decision-making or problem detection in situ.

Nowadays, portable equipment not much bigger than a smartphone, is already available, capable of analysing a multitude of products by simply selecting the right modelat any given moment. Although, it must be said, these models have to be meticulously developed by personnel who are experts in the technology, and that is what research centres such as CARTIF are here for.

It has been almost 15 years since I came across this technology thanks to a colleague who worked with it and it was out of sheer conviction that I took the baton of this great technique with which I continue to advance, learning and working, so that companies, especially in the agri-food sector, get to know it and take advantage of all its benefits.

- NIRS: Let´s not talk about “new technologies” but about good applications - 16 February 2024

- What is an online NIR and what are its uses? - 7 March 2017