From the smartphone we carry every day, the tablet or the computer, till any other portable electric tool we use in our everyday have implicit the use of an electric energy accumulation system, or what is commonly known as batteries, in this case rechargable batteries.

But, we really know what batteries are, what contain or how the materials that make them function can be recovery?

Many times the unknowledge of our environment make us carrying a bad management of some of the elements that surrounds us when they reach their service life.

Before knowing these details, could you tell me how many types of batteries exists nowadays?, we talk about Nickel Metal Hydride, Nikel Cadmium or we focus on lithium-ion, now on everyones´ lips?

- Nikel Cadmium are used mainly to feed computers, mobile phones and wireless and some varieties of toys, but they are used less and less.

- Nikel Metal Hydride are a battery variety less harmful for the environment and with a longer service life.

- Lithium-ion are the batteries with the biggest energy storage capacity in comparison with the previous ones and those that are currently most widely used.

Although this post could go on for as long as some of the encyclopaedias have volumes, those that gather dust on our shelves at home, the initial idea is to get to know lithium-ion batteries a little better and why is necessary to attend the recovery of its materials at the end of their service life.

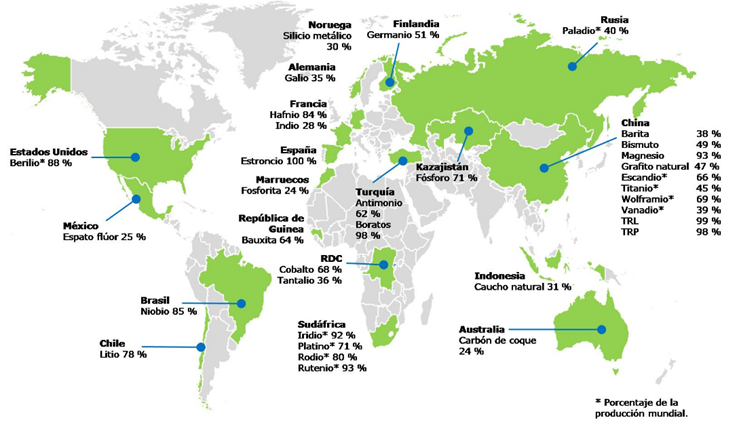

To understand the importance of this need for materials, it is necessary to understand the dependence of our European continent on raw materials, critical raw materials such as the ones that we found in nowadays Lithium-ion batteries as cobalt, nikel, lithium or manganese. Much of these materials are concentrate in very specific places of the planet, which creates a greater dependence on these.

Right, we already know that exists different types of materials inside lithium-ion batteries, but let´s make it a little more complicated, so it not only exists one type of lithium-ion battery, but, depending on its application, we talk about different chemicals, that is to say, the components that form the different cells of the batteries are based in different materials, quantities and conglomerate, as well as different morphologies. These different, lets say models, are changing since their invention at the end of the 90´s, because of their dependence on raw materials or because of the technological advances. We can count with up to 6 different types of lithium-ion batteries models. And in case you were thinking about it,yes, this will complicate their recycling.

We have already assume that we are dependent in terms of raw materials, but, in addition, we have to add the tendence to decarbonization of our energetic system, that mainly at the transport sector is tending to electric vehicle, that as we already know, uses lithium-ion batteries. Europe´s goal is to achieve carbon neutrality by 2050.

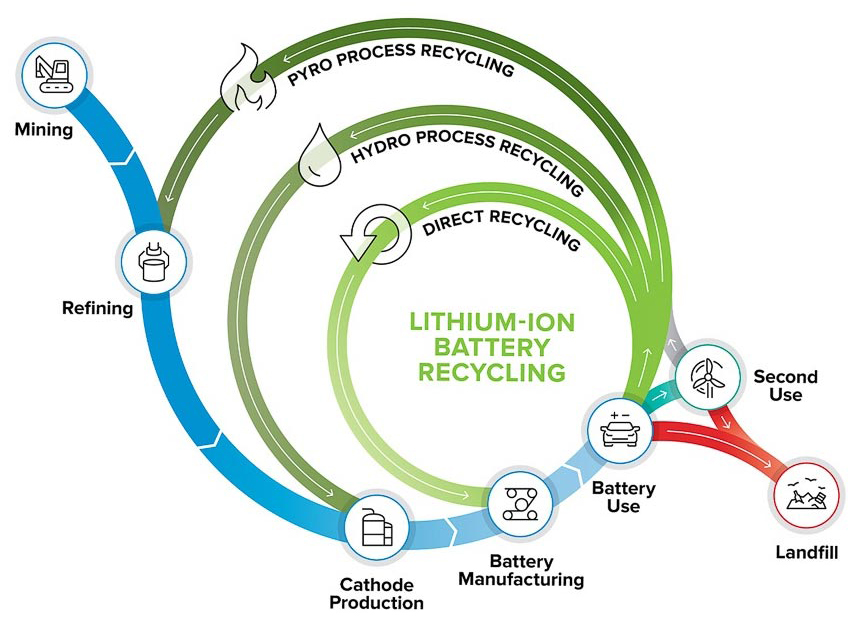

Going back to the initial question, we already know which materials make up a battery and that there are many types of them, but in addition we know the need of our european community in terms of reuse of these materials, therefore, we would have to recover those materials at the end of the lithium-ion batteries life service, but, how it is done?

Currently it exists 3 huge methods for recycling those batteries named pyrometallurgy, hydrometallurgy and direct recycling, whose influence over the value chain is next one:

- Pyrometallurgy: high temperature foundry process, it should be made up of 2 steps: first, batteries are burnt in a foundry, where the compounds are decomposed and organic materials are burnt, such as the plastic and the separator; the new alloys are generated by the ashes carbon reduction.

- Hydrometallurgy: in this process, the materials recovery is achieve by an aqueous chemistry, through the leaching in acid disolutions (or basic) and his later concentration and purification, by the evaporation or separation of the solvent. Purity and quality of the extracted metals are usually differentiated according to this last purification stage of the process.

- Direct recycling: recovery method proposed for reaconditioning and recover directly batteries active materials, preserving their oirginal structure.

If we pay attention to carbon neutrality, the first method will no longer be feasible at long term, so involves a series of green house efect emissions associated, therefore the most sustainable ways would be hydrometallurgy and direct recycling.

- Batteries in front of a new playing field - 7 July 2023

- Long life to batteries! - 22 April 2022