Computer-aided engineering tools (CAE) are more pervasive nowadays, and finite element analysis is having more impact than at any other time. In the past, CAE abilities have been used in specific fields with highly trained engineer teams and large computing facilities. For example, in the aeronautical industry the objective is, among others, to design more efficient airliners and the automotive industry must produce safer cars in case of accident.

Currently there are not field of science or engineering that has not been affected, and in some cases transformed, by computer simulation. Almost most manufacturing companies, regardless of the industry, can take advance of CAE abilities to simulate their process and improve their performance.

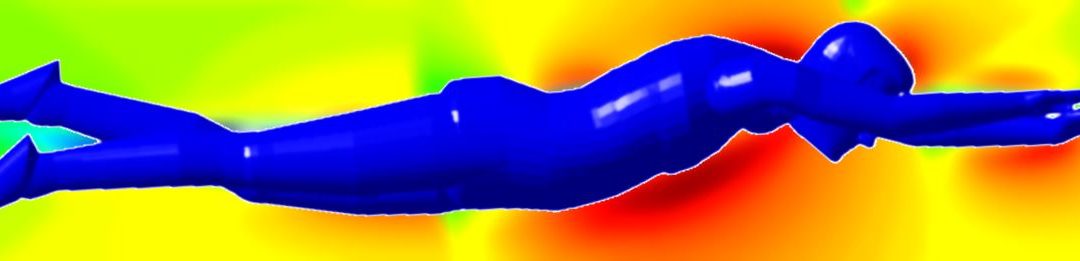

Sport industry show off this fact, for example, SPEEDO produced swimsuits including compressing effects for changing, in certain way, the shape of the swimmer’s body. Using this idea, SPEDOO designed suit able to achieve drag reductions in more than 15 per cent. In the JJ.OO. of Beijing, 94% of the medals were won by swimmers dressed with SPEDOO swimsuits (Michael Phelps, Mireia Belmonte …) and 23 out of 25 Olympic records where beaten using this technology (according to data from FINA).

For an airliner or for an Olympic swimmer the engineering problem is essentially the same. There is a shape moving through a fluid and the drag must be minimized. That is, advanced engineering aerodynamic concepts also works in the textile industry. This example clearly defines the current situation of CAE abilities, where high technology is used to solve what we could define as trifling problems.

According to Lesa Roe, NASA Langley Research Center director, “Modeling and simulation is older than NASA”. Since the first models of digital calculators, computing machines evolved step by step and around year 2000 some experts believed that engineering simulation programmes had reached its peak due to the big improvement in abilities for the limited supply of high-level engineers.

However, the more powerful computers and the friendly integrated analysis environments have allowed companies to take advantage of the enormous potential of simulation programmes to make accurate predictions about natural phenomena, providing compelling evidence that we are really gaining in our understanding of how the products, processes and services can be optimized. Therefore, the almost endless engineering simulation techniques provide big growth opportunities, based on the current needs and the challenges that this poses.

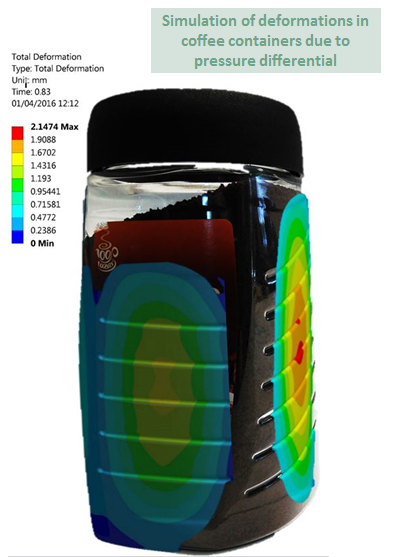

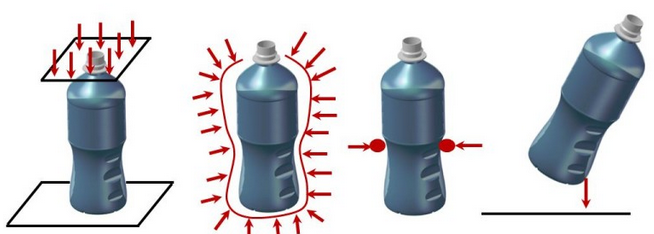

As the saying goes, “Necessity is the mother of invention” CARTIF believes and works in endless possibilities to help customers develop better products and processes. I would like to stress in a particular application: the estimation of the static and buckling behaviour of very thin walled containers for food packaging.

Through simulation programmes we are able to detect weak points and design failures prior to manufacture, with consequent savings in time, material and money. Note that the containers are manufactured by plastic injection machines using expensive cast moulds. During the analysis are taken into account parameters such as constitutive material properties (PET, HDPS, aluminium …), thickness, type of liquid or granular product to be content, etc. that define the containers and allows us to predict its performance, resulting in deformation curves under load, loads of collapse, tensions and stretching under certain loads which it may be subjected to circumstances of the production process, storage and transport conditions, including temperature, pressure and impact effects among others.

Beside theses services, being aware that “data is the new currency”, CARTIF is also working on structural health monitoring in civil structures. The aim of this work is predict when maintenance will be needed or what the expected behaviour of structure should be if the real system begins to deviate from the digital models’ behaviour. This idea can be reviewed in my previous post ‘When structures age’.

- How does the term “metal-eco-additive manufacturing” sound? - 27 December 2024

- Beyond strategy. Smart use of engineering expertise. - 23 December 2022

- Infinite progress through finite elements - 30 May 2017