The importance of the design tools and green hydrogen optimisation

Green hydrogen is positioning itself as a viable alternative in the context of the transition towards clean and sustainable energy sources. Not only does this energy carrier transform energy without emitting pollutants, but it also has significant long-term storage capacity, which helps to address one of the main problems of renewable energy sources such as solar and wind: their intermittent and seasonal nature.

Due to the several hydrogen applications and the variable nature of renewable sources, the design and optimisation of green hydrogen production, storage and utilisation systems are complex processes especially when applyied to industrial processes, where careful management of the entire chain is necessary to ensure continuous and efficient operation. This is where simulation and optimisation tools plays a crucial role, facilitating the efficient integration of hydrogen into the energy system and enabling optimal decisions to be made based on detailed data and accurate projections.

Need for specialised tools for energy transition

In order to move towards a more sustainable and decarbonised energy system, it is essential to apply dynamic modelling and simulation to optimise both the production and use of green hydrogen in the residential, industrial and heavy transport sectors, as each has different energy demand patterns, requiring the development of specific tools to evaluate multiple scenarios, optimise design and determine the most appropriate control and management strategies.

These tools not only allow the simulation of system behaviour under real conditions, but also help to optimise important parameters such as electrolyser power ratings, hydrogen storage volume and the management of optimal times to consume or storage energy. The application of advanced optimisation algorithms aims to reduce operational and investment costs while maximising the use of renewable energy by ensuring that the best technical, economical and ecological decisions are made.

Functionalities of the developed tool

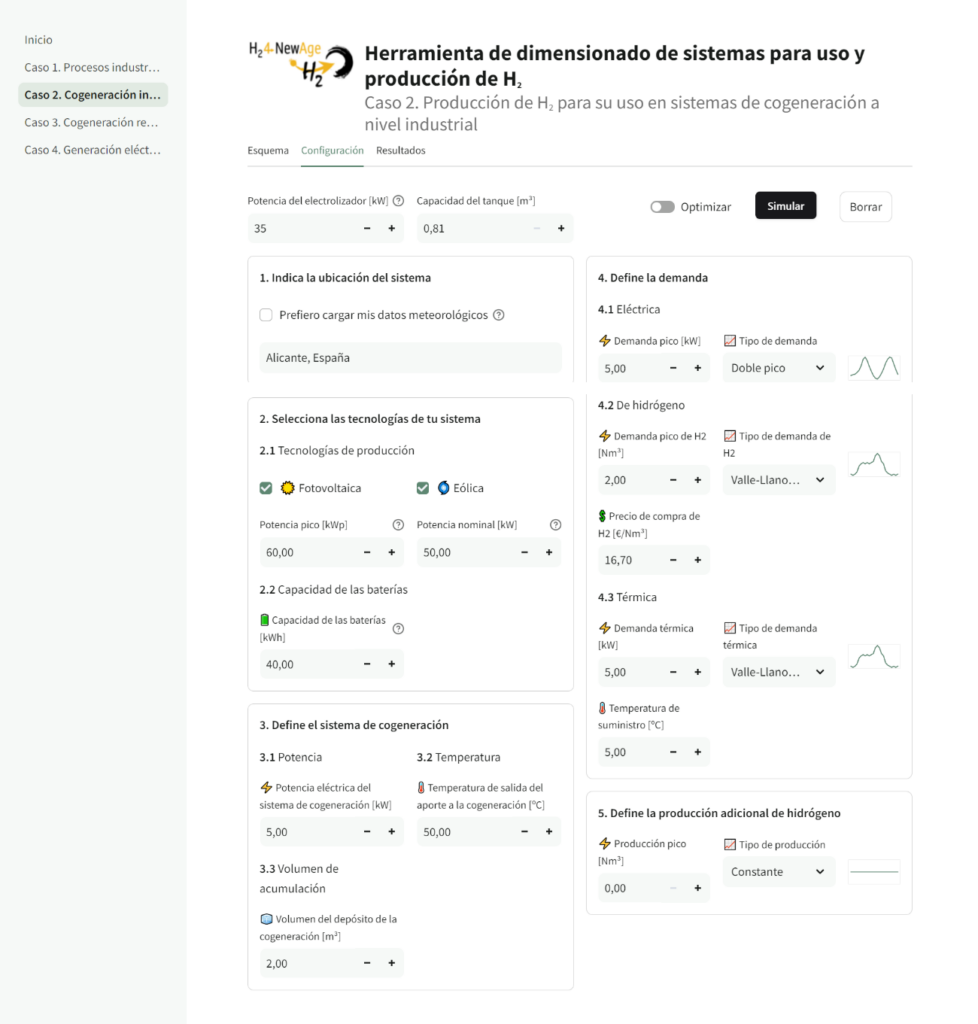

CARTIF which is a Cervera Centre of Excellence, awarded by the Ministry of Science and Innovation and the CDTI, under the files CER-20191019 and CER-20211002 has developed a tool for the design and optimisation of this type of systems thanks to the CERVERA H24NewAge project. It is a platform that enables the design and optimisation of systems for the production and use of green hydrogen in residential and industrial environments by applying dynamic modelling together with Python through an easy-to-use web interface that facilitates access to complex simulations without the need for advanced technical knowledge, contributing to the democratisation of hydrogen technology, allowing users with different levels of experience to interact with complex models and gather useful information for decision-making in the design of their systems. Some of the key points of the tool are:

- Simulation of hydrogen production scenarios: Users can simulate a variety of hydrogen production environments, such as industrial processes, industrial cogeneration, residential micro-cogeneration and large-scale power generation.

- Optimisation Based on Advance Algorithms: The tool helps to size the optimal size of system components, minimising costs and maximising renewable energy utilisation using advanced optimisation algorithms. It also includes the creation of operational strategies that consider renewable energy availability, hydrogen demand and storage constraints to achieve economical and efficient operation.

- Flexibility and Adaptability: Crucial parameters such as geographic location, demand profiles and renewable production technologies can be adjusted through the platform, making it ideal for a variety of scenarios and specific needs. This capability is fundamental for users to assess how their designs would perform in different situations and scenarios, adapting hydrogen production and storage technologies to the particularities of each environment.

- Visualization of results: The tool’s web interface makes it easy to visualise simulation results through interactive graphs and tables showing key aspects of the system, such as energy efficiency, operating costs and storage capacity. Users can also compare the results of different scenarios, which is essential for identifying opportunities for improvement and making further adjustments.

Conclusions

Ultimately, tools such as these can be used to evaluate and optimise strategies for the production and use of green hydrogen, facilitating its integration into the energy system and contributing to a more sustainable future. Thanks to access to advanced models and optimisation algorithms, these tools enable informed decisions to be made, resulting in more efficient and resilient systems. A clear example would be the optimal hydrogen storage capacity, the correct estimation of which can avoid unnecessary costs and ensure a constant supply, increasing the operational efficiency of the system. In addition, the ease of use and flexibility offered by these platforms help reduce the technical barriers to adopting green hydrogen, making it an accessible and viable option for a wider range of users and applications. This is key to moving towards an effective energy transition and to fostering solutions that reduce dependence on fossil fuels and support climate change mitigation.

Co-authors

Jesús Samaniego. Industrial Engineer. Since 2002 he has been working at CARTIF in the development of projects within the field of energy efficiency, the integration of renewable energies and in the study of the quality of the electricity supply

- Hydrogen. Green that I want you to design green - 8 November 2024

- From consumer to prosumer - 26 February 2021