In the fight against climate change, technological innovations is one of our most powerful allies. One of the most promising and challenging areas in this regard is the transformation of carbon dioxide (CO2), a prevalent greenhouse gas, into useful raw materials for industry and transport. This approach not only promises to mitigate greenhouse gas emissions, but also opens the door to a circular economy where waste becomes a resource.

Challenges and opportunities of CO2 as raw materia for industry

CO2 is the main contributor to global warming, arising mainly from the burning of fossil fuels and deforestation. The concentration of CO2 in the atmosphere has unprecedented levels, making it imperative to find effective ways to reduce these emissions. Capturing and utilising of CO2 is a promising strategy, transforming this gas into valuable products, which could revolutionise sectors such as transport and manufacturing, significantly reducing our carbon footprint.

Converting CO2 into value-added products: key technologies to meet the challenge of decarbonisation of industry and economy

CO2 transformation into raw materials involves several methods, including electrochemistry, catalysis and biotechnology. These technologies aim to convert CO2 into fuels, plastics, building materials and other industrial chemicals, which basically fall into three types:

- Biotechnology: based on biological fermentation processes with gas-liquid phase substrate. It uses genetically modified organisms, such as microalgae and bacteria, to absorb CO2 and convert it into biofuels an chemicals. This approach offers the potential for highly sustainable processes that can operate under ambient conditions.

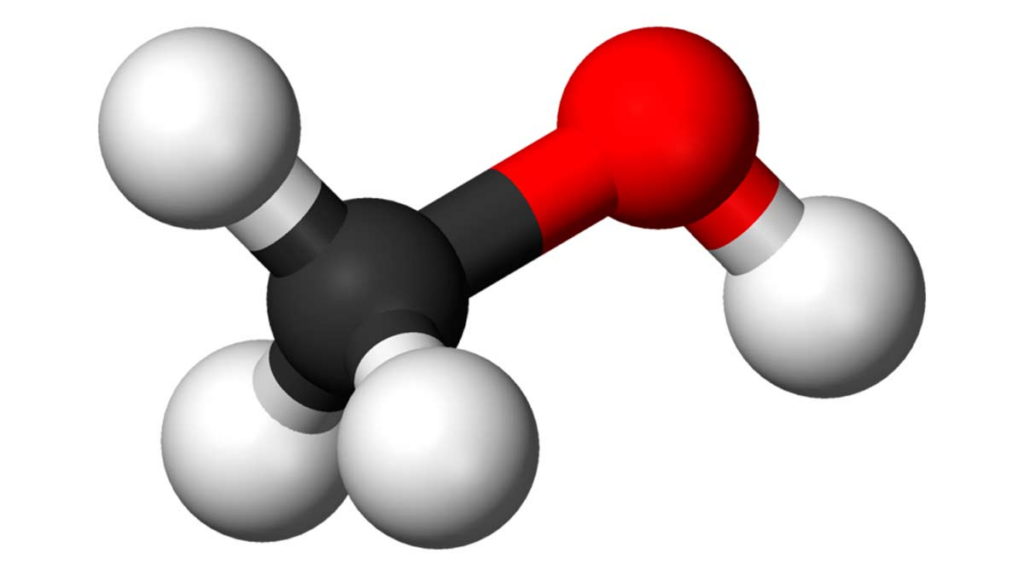

- Electrochemical technology: based on the use of electrical energy and potential difference between two electrodes to reduce CO2 into value-added chemicals (e.g. methanol, formic acid, etc.) which can be used as e-fuel, H2-bearing green molecules, or chemical precursos for industrial use. The efficiency of these processes has improved significantly, but they still face challenges in terms of scalability and costs.

- Chemical-catalytic processes: based on the use of catalysers to active and accelerate the chemical reaction and transformation of CO2 into value-added products (methane, methanol, dimethyl ether, ,etc.)Current research lines are exploring new catalysts that can operate at low temperatures and pressures, making the process more energy efficient and economically viable.

On the other hand, CO2 transformation faces technical, economic and regulatory hurdles. Energy efficiency, cost reduction and integration of these technologies into existing infrastructure are key challenges. In addition, a regulatory framework is required to promote investment in these technologies and the use of CO2 products.

Despite these challenges, the capture and uses of CO2 as a renewable carbon source and to contribute to the decarbonisation of industry and transport, offers an unprecedented opportunity to mitigate climate change and advance towards a more sustainable and circular economy. By turning a problem into a solution, we can unlock new pathways for environmental sustainability, technological innovation and economic growth. Collaboration between governments, industries and scientific communities will be essential to overcome these challenges and harness the potential of these technologies for a greener future.

R&D projects such as CO2SMOS, coordinated by CARTIF´s Biotechnology and Sustainable Chemistry area, aims to develop a set of innovative, scalable and directly applied technologies in the bio-based industries sector that will help to convert biogenic CO2 emissions into value-added chemicals for direct use in the synthesis of low carbon footprint material bioproducts. To this end,and integrated hybrid solution is proposed that combines innovative technologies and intensified electrochemical/catalytic conversion and precision fermentation processes, together with the use of renewable vector soruces such as green H2 and biomass. Key elements to achieve the indsutry´s goal of zero-emissions and climate neutrality.

- The green molecule revolution - 15 November 2024

- Biogenic CO2: challenges and opportunities for a sustainable future - 19 April 2024