Traditionally, factors that were taken into account in manufacturing processes were economic, management, production, etc. However, this situation has changed in recent years. Energy efficiency and sustainable management are fundamental aspects that many companies have incorporated in their processes. Aware of that reality, CARTIF is accompanying the companies to incorporate in them the “Factories of Future” concept. An example of work done is the REEMAIN project.

REEMAIN moves toward zero carbon manufacturing and Energy Efficiency 2.0 through the intelligent use of renewable energy technologies and resource saving strategies that consider energy purchase, generation, conversion, distribution, utilization, control, storage, re-use in a holistic and integrated way.

In addition to that, REEMAIN project has provided us with the opportunity to expand our knowledge and experience in the Resource and Energy Efficient Manufacturing world. During the demonstration actions at the factories, the team has experimented energy and materials saving technologies and process and, of course, tested their effectiveness.

As the project comes to an end, we have produced a Best Practices Book as a way of sharing our experience with other professionals in the material and energy efficiency manufacturing domain.

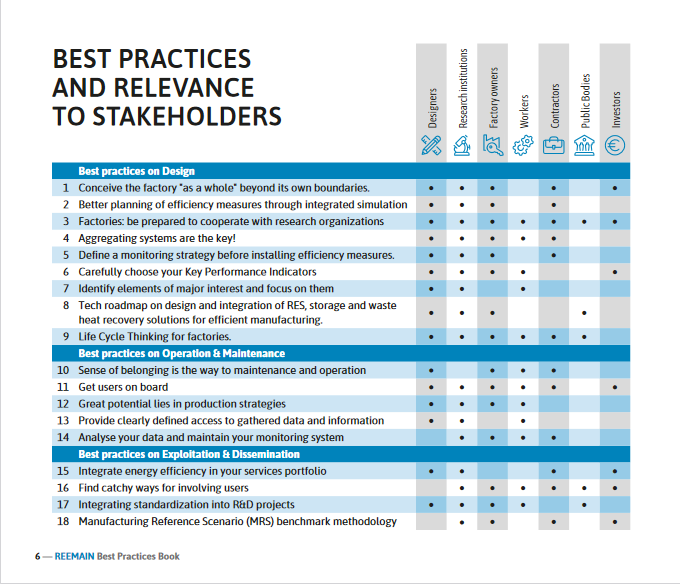

The REEMAIN Best Practice Book summarises the key findings from our experience of over four years working on the project and are recommendations we make to the overall community involved in this kind of projects (designers, research institutions, factory owners, workers, contractors, public bodies, investors, etc.), in order to provide a help if some of them decide to get involve in an efficiency improvement project within a factory.

18 Best Practices are featured. They were based on our experience while searching and testing efficiency measures in our three demo factories: GULLON (Biscuit), BOSSA (Textile) and SCM (Iron & Steel). Three main thematic areas had been identified: Best practices on “design”, best practices on “Operation and maintenance” and “Exploitation & Dissemination”.

Each of them is presented in a short and visual way. They are composed of: title, description (being itself a recommendation), stakeholders, replicability, practical guidelines and things to avoid, impact rating, and finally the REEMAIN practical experience.

The Best Practice Book is available online for download free.

- PLADEMI: access to energy services for development in Ibero-America - 16 June 2023

- Reduction of costs and emissions in factories: real cases - 18 May 2018

- Best practices in energy efficiency in industry projects - 21 September 2017