Water is essential for human survival and well-being and plays an important role for many economic sectors. However, water resources are unevenly distributed in space and time, and are under pressure from human activity and economic development.

In addition to water for irrigation and food production which puts one of the greatest pressures on freshwater resources, industry is also a major water consumer, accounting for between 10% (Asia) and 57% (Europe) of total water consumption, either for the production of its products, and/or for the maintenance of its materials and equipment. All industrial sectors make use of water for industrial processes, ranging from those that manufacture foodstuffs to those that manufacture electronic devices.

Wastewater management is also one of the most important environmental problems facing society today, and is therefore an issue that transcends purely industrial activities, since as a vital substance, water is an ecosystem service that is transversal to most human activities, and whose traceability is heavily regulated by governmental and environmental agencies.

The possibility of reusing industrial water, regardless of whether the intention is to increase water supply or to manage nutrients in treated effluents (also a factor leading to water reuse), has positive benefits that are also the main motivators for the implementation of reuse programmes in companies.

Water Consumption in Industry – Management and Saving Plan

Industries can make better use of water, machinery, processes, services and accessories that demand large quantities of this resource that can be reduced with efficient use techniques.

For each type of industry, water is essential to satisfy different needs, and it is common to prioritise water consumption for cleaning and disinfection of products or installations and equipment. In these cleaning and disinfection tasks, the volume of water consumed varies according to the size, equipment and facilities, and the potential for savings is significant.

Therefore, water reuse should be examined from a circular economy perspective and the opportunities and risks of water reuse in the transition to a circular economy should be investigated for each type of industry.

The objectives of creating a water consumption management and saving plan in companies are:

- Define methods to find out the water consumption in the facilities.

- Identify strategies and points for improvement in the water consumption actions of the facilities and assess their feasibility.

- To implement an effective system to reduce and control this water consumption.

- Promote the participation of workers.

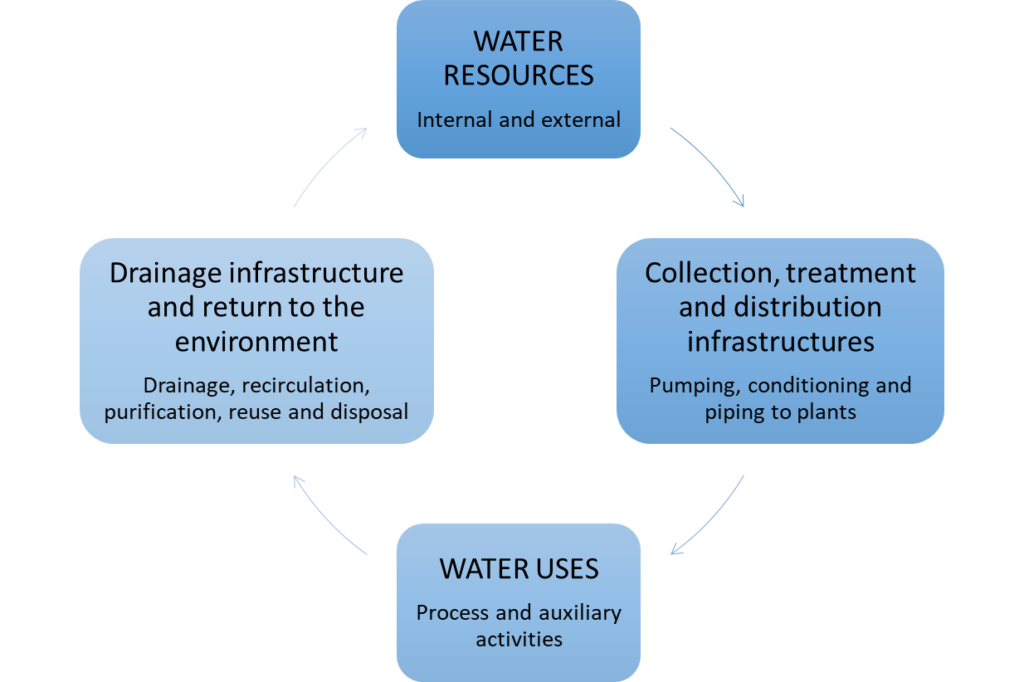

The integral water cycle in industry

The transition to a circular economy encourages more efficient water use and, together with incentives for innovation, can improve an economy’s ability to cope with the demands of the growing imbalance between water supply and demand.

From a circular economy perspective, water reuse is a win-win option. The full cycle of wastewater management is a key component of the cycle, from source, through distribution, collection (sewerage and sanitation systems) and treatment to disposal and reuse, including water, nutrient and energy recovery. Circular economy initiatives aim to close resource loops and extend the useful life of resources and materials through longer use, reuse and remanufacturing.

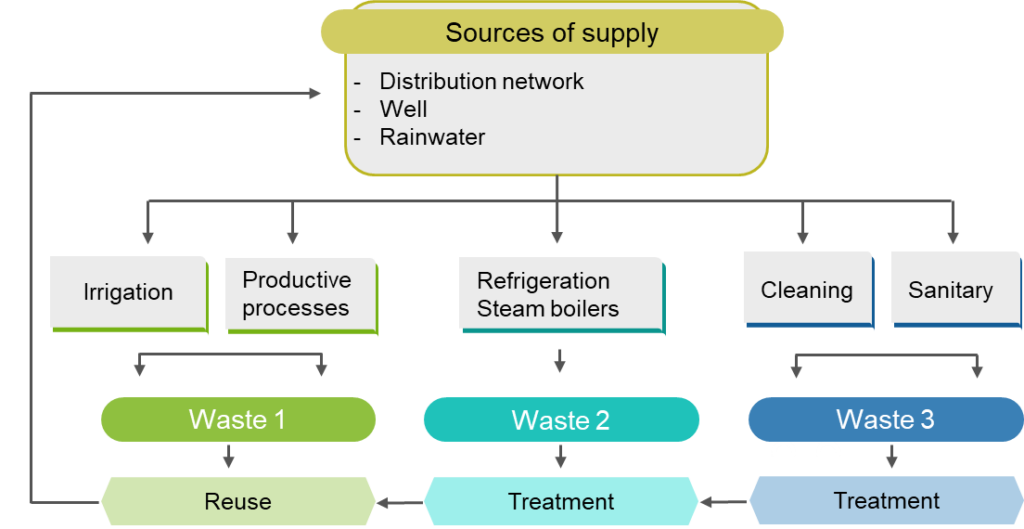

The selective segregation-correction of segregated effluents from the different industrial activities (process water, cleaning, cooling, boilers, sanitary, etc.) favours the recirculation of water and the reuse of the company’s own treated water, as well as the reuse of grey water. It also minimises water consumption, reduces the final volume of water to be treated or managed and increases the efficiency of the final treatment process.

In general, water reuse requires physico-chemical treatment processes, connections, waste disposal mechanisms and other systems. The level of treatment will depend on the quality of water required for the proposed use.

The implementation of water management and water savings to be optimised is described by means of the 9 elements that make up the integral water cycle in industry:

- Supply sources: distribution network, own wells, rainwater, etc.

- Specific treatment depending on the quality requirements for the different types and uses of water.

- Piping to the facilities.

- Uses in the process (supply to product, reaction medium, dilution, etc.) and auxiliary activities (cooling towers, steam boilers, cleaning of equipment and facilities).

- Effluent drainage.

- Recirculation.

- Purification (own or external WWTP).

- Internal reuse.

- Discharge of wastewater, quality requirement limited by the competent environmental authority.

Water consumption in industry can be rationalised and minimised through various improvements in the production process and auxiliary activities, taking as a reference the application of BATs (Best Available Techniques in relation to integrated environmental authorisations in industrial activities).

As a rule, general actions concern the modification of open cooling circuits into closed ones, the avoidance of losses in steam systems, the improvement of inlet water conditioning systems and production means, and the optimisation of cleaning operations of equipment and installations.

Recirculation is considered if water treatment is not necessary or is very simple, as it involves the successive use of a flow of water in the same process, consuming a small percentage of flow renewal in each cycle.

Internal reuse is the use of water already used in the industry itself, treated by a specific treatment, for other uses that are less demanding in terms of quality or sensitivity.

Non-conventional resources such, as rainwater harvesting, are an easy way to obtain water and do not require purification, but depends on the amount of precipitation in each location. It offers advantages such as high physico-chemical water quality without the need for purification and a simple infrastructure.

The reuse of greywater from showers and toilets with a low level of contamination can be treated into clean, non-potable water.

Operational methodology for optimising water consumption and management

The procedure is summarised as follows:

STEP 1

Data collection and analysis. Request for previous documentation and data necessary for the evaluation of water management.

STEP 2

Visit to the company to recognise “in situ” the corresponding characteristics of the production processes developed, as well as the use of water in the plant.

STEP 3

General description of the production processes and auxiliary activities, identifying the different operations: process line, water line, treatment lines and auxiliary activities (refrigeration, steam boiler, cleaning of equipment and containers and storage).

- Diagram/plan of water use in the company.

- Substances involved, raw materials, reagents, by-products.

- Inventory and description of ancillary activities.

- Inventory, origin, handling and destination of effluents, wastes and emissions.

STEP 4

Report writing:

- Diagnosis of minimisation of water consumption and proposal for improvement.

- Prioritisation of actions according to their performance.

Essentially, the fundamental strategy for the optimisation of water management is the global characterisation of water use, the application of selective segregation-correction of process effluents and the analysis of the possible recovery and utilisation of these effluents.

Optimising water management in industry can achieve savings of 40-50%. This can reduce costs and protect natural resources. Companies should be aware that this increases the social prestige of the company with an economic benefit and promotes sustainability.