The majority of plastics used in the world today come from non-renewable and non-biodegradable sources. In an effort to reduce the impact of plastics on the environment, alternative methods of production and waste management have been studied for decades. Several microorganisms have the ability to produce plastics naturally, using different substrates, which are biodegradable and biocompatible under certain conditions.

During the last few years, acidogenic fermentation for the production of volatile fatty acids (VFA) has been identified as a promising approach to utilise organic waste as a valuable resource. VFA have a wide potential for applications ranging from carbon source for biological nutrient removal processes to use as a bioenergy resource for the generation of hydrogen and liquid biofuels. VFA-rich streams produced from organic waste fermentation can also be used as biopolymer precursors in the bioplastics industry, as they are a suitable feedstock for the production of polyhydroxyalkanoates (PHA).

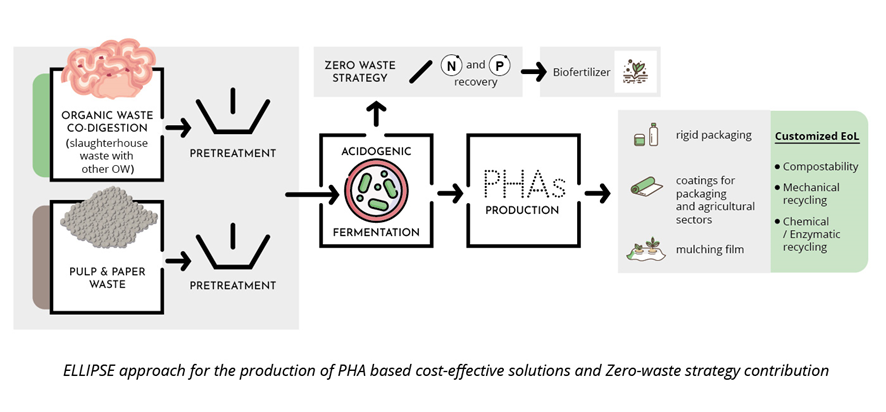

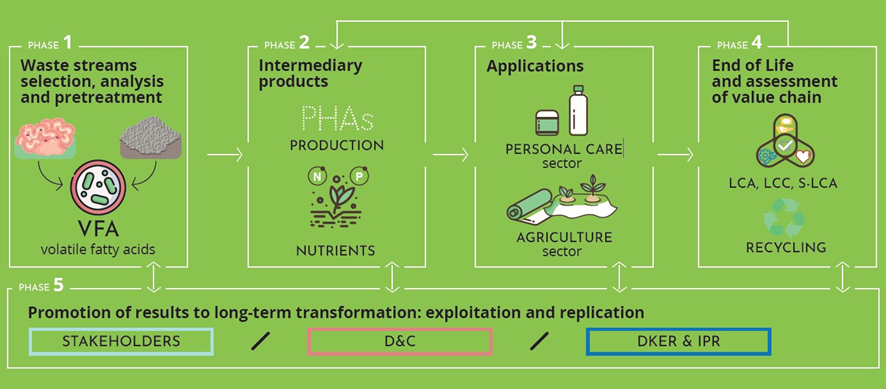

To address the growing problem of bio-waste generation and the increasing demand for bio-based feedstocks, the ELLIPSE project is working in the biotechnology sector with the aim of valorising heterogeneous waste streams generated in significant quantities in Europe, slaughterhouse waste (contained in the belly or rumen) and paper and pulp sludge, to produce cost-effective polyhydroxyalkanoates (PHA) for agricultural and personal care applications, through co-processing with other organic wastes such as sludge from the dairy industry and glycerol from the biodiesel industry, as well as nutrient recovery to produce bio-based fertilisers. The integration of these waste streams as biorefinery feedstocks will reduce landfill waste volumes, open up new pathways for the production of chemicals and bioplastics and, at the same time, create additional income for the related industries that generate them, with the added benefits of water recycling, reduced soil degradation, groundwater contamination and methane emissions.

PHA belongs to a family of 100% bio-based polymers with versatile biodegradability properties in most environments, recyclable and exhibiting a wide range of physical and mechanical properties depending on their chemical composition, from the very flexible poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) to the rigid polyhydroxybutyrate (PHB), showing similar properties to some fossil-based materials such as polypropylene (PP) and polyethylene (PE) and better gas and liquid barrier properties than other bioplastics such as polylactic acid (PLA), being a good biodegradable and compostable alternative in agricultural and personal care applications.

One of the objectives is to maximise the production of VFA derived from acidogenic fermentation by optimising the process using innovative technologies, such as the use of an anaerobic membrane bioreactor (AnMBR). The project contributes to the circular economy by promoting sustainability and zero waste by demonstrating the technical feasibility of recovering nutrients from the waste stream (digestate) through a hybrid autotrophic-heterotrophic process of microalgae cultivation, which results in the production of a biofertiliser.

The project has 5 phases dealing with pre-treatment of waste and obtaining VFA, production of PHA, possible applications of bioplastics, life cycle analysis study and exploitation of the results.

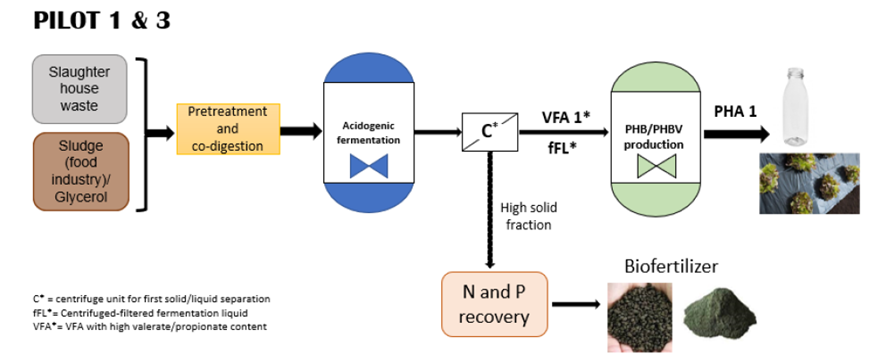

Pliot plants of the ELLIPSE project

In Pilot 1, pre-treatment and valorisation of sludge from the processing of slaughterhouse waste for the production of rigid packaging and plastic mulch will be carried out. A co-digestion of raw materials will be carried out in order to ensure the most optimal conditions for producing VFA.

Pilot 3 will be developed simultaneously with Pilot 1 to recover N and P nutrients for biofertiliser production. Different technologies will be validated:

The biological technology of the hybrid autotrophic and heterotrophic microalgae culture system, and the physical methods of pressure-drive membrane technology (ultrafiltration and reverse osmosis) and membrane contactors, to recover ammonia, as ammonium sulphate.

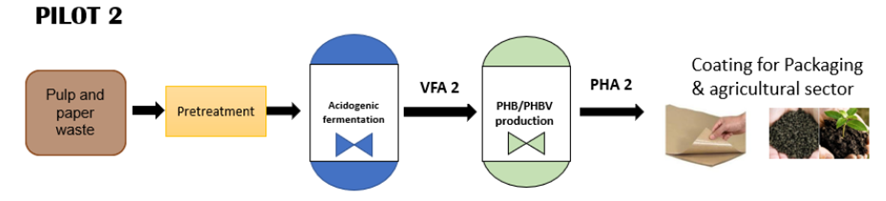

Pilot 2 will treat and recover waste from the paper industry to produce bioplastic coatings for the personal care and agricultural sectors.

The demonstration of the possibility to transform complex bio-waste stream into high-value bio-based and biodegradable products in multiple sectors, accompanied by the validation of multiple end-of life routes for the biobased and biodegradable products achieved within the project will provide novel and tangible results for further promoting public awareness and acceptance of biodegradable and bio-based solutions. Apart from all this, during ELLIPSE project the pulp and paper industry will be able to utilize products (PHA coated paper for flexible packaging as counterpart of current PE coated paper) produced from its wastes. This is a good showcase for circular economy and has the potential to increase awareness and acceptance of bio-based solutions.