Geolocation systems are reaching indoors

With global positioning systems, a phenomenon similar to what happened with mobile phones has occurred: in a few years we have gone from non-existence to consider it essential. The truth is that, in fact, geolocation is one of those technologies that has led to the development of many applications and in many areas is not conceived to work without the use of commonly called GPS.

These types of positioning systems are based on receiving the signal from three or more satellites and using trilateration: position is obtained in absolute coordinates (usually WGS84) by determining the distance to each satellite.

Global positioning systems based on satellites have their origin in the US system TRANSIT in the 60s. With this system you could get fix the position once an hour (at best) with an accuracy of about 400 meters. This system was followed by the Timation system and in 1973 the Navstar project began (both from USA). The first satellite of this project was launched in February 1978 and full operational capability was declared in April 1995. This Navstar-GPS system is the origin of the GPS generic name we usually apply to all global navigation systems. In 1982 the former Soviet Union launched the first satellite of a similar system called GLONASS that became operational in 1996. Meanwhile, the People’s Republic of China in 2000 launched the first satellite of BeiDou navigation system, which is scheduled to be fully operational in 2020. Finally, in 2003, it began the development of the positioning system of the European Union called Galileo, with a first launch in 2011. Currently there are 12 satellites in active (and 2 in tests) and the simultaneous launching of four more is scheduled on 17 November 2016. This way, 18 satellites will be in orbit and initial service of Galileo positioning system could begin in late 2016. It is expected to be fully operational in 2020. It must be said that there are also other systems, complementary to those already mentioned, in India and Japan in a local range.

As you can see, the global positioning systems are fully extended and are widely used both military and commercial level (transport of people and goods, precision agriculture, surveying, environmental studies, rescue operations …) and on a personal level (almost everyone has a mobile phone with GPS available, although their battery always run out at the worst moment).

Regarding the precision obtained with current geolocation equipment, it is about a few meters (and even better with the Galileo system) and can reach centimetre accuracy using multifrequency devices and applying differential corrections.

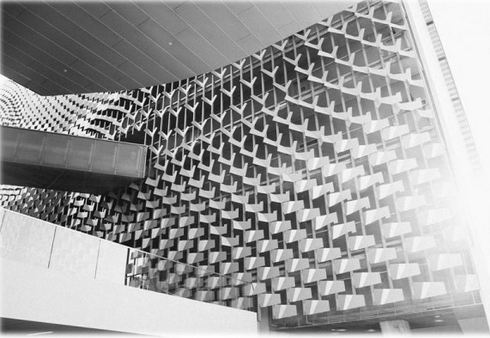

One of the problems of these systems is that not work properly indoors since the satellite signal cannot be received well inside buildings (although there are highly sensitive equipment that reduce this problem and other devices called pseudolites, acting simulating the GPS signal indoors). And of course it’s not enough to know our exact position outdoors but now comes the need to also be located inside large buildings and infrastructure (airports, office buildings, shopping centres, …).

So indoor positioning systems (IPS) have appeared allowing location inside enclosed spaces. Unlike global positioning systems, in this case there are many different technologies that are usually not compatible with each other making it difficult to dissemination and adoption by the general public. There are already very reliable and accurate solutions in enterprise environments but these developments are specific and not easily transposable to a generic use of locating people indoors. In this type of professional context, CARTIF has done several projects indoor positioning for autonomous movement of goods and service robotics. There is not a standard indoor positioning system but there are many technologies competing for a prominent place.

The technologies used can be differentiated on the need or not of a communications infrastructure. Those who no need existing infrastructure are often based on the use of commonly available sensors in a smartphone: variations in the magnetic field inside the building that are detected by the magnetometer, measuring the movements by using accelerometers or identifying certain feature elements (such as QR codes) using the camera. In all these cases the accuracy achieved is not very high but may be useful in certain applications as simple guidance in a large building.

Indoor positioning systems using communications infrastructure exploit almost all available technologies of this kind for the location: WiFi, Bluetooth, RFID, infrared, NFC, ZigBee, Ultra Wideband, visible light, phone masts (2G / 3G / 4G), ultrasound, …

With these systems, the position is usually determined by triangulation, calculating the distance to the fixed reference devices (using the intensity of the received signal, coded signals or by direct measurement of this distance). Thus you can reach greater precision than in the three previous cases. There are also new developments that combine several of the above technologies in order to improve the accuracy and availability of positioning.

Although, as has been said there is no standard, the use of systems based on Bluetooth low energy are spreading (BLE nodes). Examples of such systems are the Eddystone (from Google) and iBeacons (Apple).

Logically, as in the case of outdoor positioning the corresponding environment map is required to allow navigation. There are other systems, called SLAM, which generate environment maps (which may be known or not) as they move, widely used in robots and autonomous vehicles. A recent example is the Tango project (from Google once again) that generates 3D models of the environment just using mobile devices (smartphones or tablets).

As we have seen, we are closer to be located anywhere, which can be very useful but also can make us overly dependent on these systems while the usual privacy issues concerning positioning systems are increased. So although thanks to these advances the sense of orientation is less necessary, we must always keep common sense.