The construction industry is undergoing a quiet revolution. While cranes and excavators continue to take centre stage on construction sites, a new type of worker is gaining ground: collaborative robots, or “cobots”. These efficient helpers will transform the way we construct and rehabilitate buildings. But what exactly are they and how can they change the rules of the game?

Cobots: More than simple machines

Unlike traditional industrial robots, cobots are designed to work side by side (or rather, arm in arm) with humans. These robots are equipped with sensors that allow them to detect the presence of people and objects in their environment. In this way, they can adapt their movement and strength to work safely alongside human workers. In the field of construction, these robots can be of great help, especially in the heaviest, most repetitive and dangerous tasks.

Façade rehabilitation: a new approach

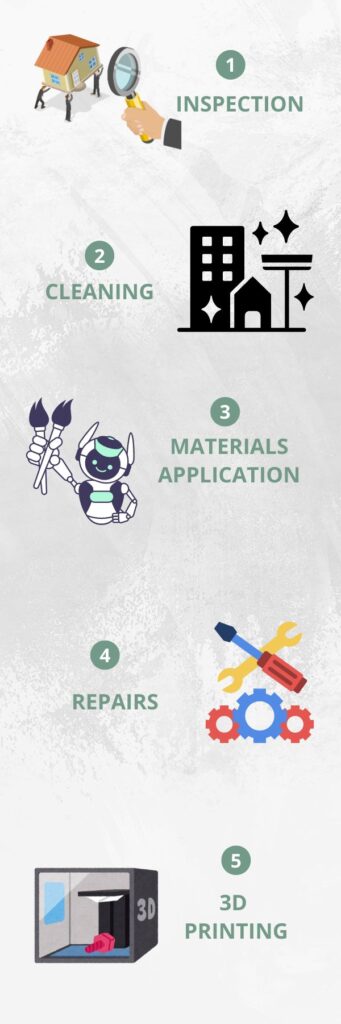

Façade rehabilitation is an area where cobots can be of particular value. These tasks are often labour-intensive, dangerous and require high precision. There are several tasks where these devices could be of great use.

- Inspection: Equipped with high-resolution cameras and sensors, the cobots can examine every inch of a façade in detail, detecting cracks, dampness or flaws that might go unnoticed by the human eye.

- Cleaning: Specialised robots can clean façades efficiently and uniformly, without putting scaffolding workers at risk.

- Application of materials: Whether it is paint, sealants or coatings, cobots can apply materials with high precision and consistency. In addition, material waste is significantly reduced, as they would use the exact amount needed in each case.

- Repairs: Some advance cobots can perfom minor repairs, such as filling cracks or replacing deteriorated elements.

- 3D Printing: 3D printing using cobots makes it possible to create intricate shapes and patterns that would be extremely difficult or costly to achieve with traditional methods. In this way, each façade can be unique, perfectly adapted to the aesthetic and functional needs of the building and its surroundings. In addition, it is possible to directly print elements such as thermal or acoustic insulation within the façade structure. In this context, European projects in which CARTIF collaborates, such as INPERSO, are actively working on the integration of cobots for the rehabilitationf and 3D printing of façades.

Profit beyond efficiency

The intorduction of cobots in façade renovation not only improves the efficiency and quality of work, but also brings other benefits. In the area of safety, for example, by performing the most dangerous tasks, cobots significantly reduce the risk of occupational accidents. They also help in sustainability by optimising the application of the requires amount of material and thus reducing waste. Finally, they also facilitate traceability and documentation of the work performed. The data collected during robotic inspections provides a valuable digital record of the building´s condition.

Challenges and considerations

Despite their potential, the use of collaborative robots in construction still faces some challenges. One of them is related to existing regulations. Building regulations need to be adapted to include this new technology. This problem is common in many areas where innovations are ahead of regulations. Research is also needed on the long-term performance of the new materials associated with these techniques and the durability of the structures created. Finally, the initial costs of these robotic systems need to be considered. Although it may be cheaper in the long term, the initial investment in this technology canbe significant and requires a payback time that needs to be assessed.

Human factor

Despite all these advances, it is important to remember that cobots aren´t here to replace human workers, but to complement them. Construction professionals are still essential for planning, decision-making and tasks that require a human touch and creativity. One of the goals of using such robots is to free workers from the heaviest, most repetitive and dangerous tasks.

Looking to the future

As technology advances, we can expect to see even more sophisticated cobots on our construction sites. Imagine robots that can communicate with each other to coordinate complex tasks, or use artificial intelligence to adapt their working methods to the specific conditions of each building. Human-robot collaboration in building construction and renovation is not just a passing trend, but the future of the industry. With every façade rehabilitated and every building constructed, cobots are proving their worth, moving towards a more sustainable and safer future for the construction industry. These technologies can not only change the way we build, but also how we conceive the function and design of buildings. As technology advances, we can expect to see buildings that are not just structures, but truly functional and sustainable works of art.

- Collaborative robots: new work employees on construction - 31 July 2024

- New strategies (and technologies) against huge forest fires - 11 February 2022

- Improvement of the road maintenance through Artificial Intelligence - 29 October 2021