Biogas as an energy source is becoming more and more popular, but what is biogas and how does it differ from natural gas? The difference is that natural gas is a fossil fuel, while biogenic gas is renewable.

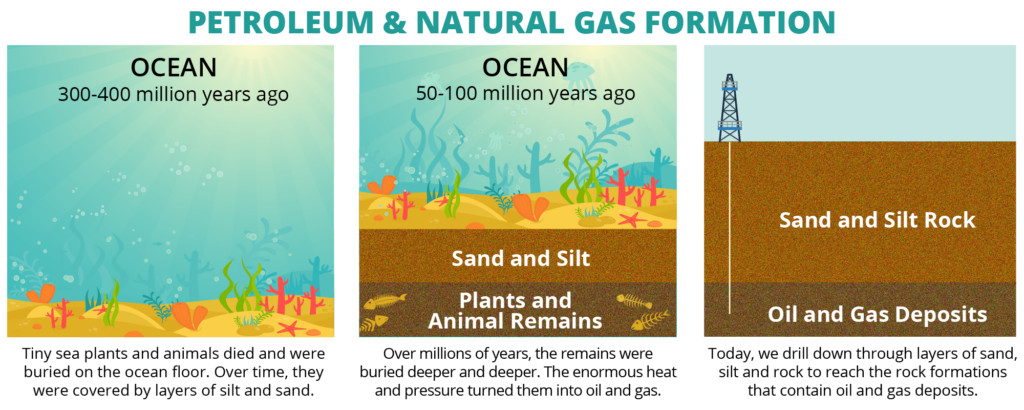

Natural gas was formed millions of years ago, at the age of the dinosaurs, like oil or coal. The accumulation of plankton as well as animal and plant rests on the seabed, buried by layers of soil, caused it to be produced in anaerobic conditions, that is, without oxygen.

Biological bacteria decomposed the organic matter and the gases generated bubbled upwards, and where there was an impermeable layer, they accumulated, giving birth to gas pockets or reservoirs. It is therefore a finite resource; once it is exhausted, there will be no more to supply human energy demands.

Natural gas consists mainly of methane, ethane and carbon dioxide, although it usually has other components or impurities, so the energy is obtained by combustion, compared to other fossil fuels it is more efficient and cleaner in terms of emissions, although it depends on the impurities.

Biogenic gas is also produced by the decomposition of organic matter under the action of bacteria, in the absence of oxygen, which is why it is also called Biogenic Natural Gas, but in this case in a tank with controlled conditions of temperature and pressure.

But in biogenic gas, the organic matter used comes from by-products of farms, crops or industries, so it is a renewable energy. The composition of biogenic gas is similar, but with fewer impurities, as the quality is improved by upgrading, which is explained in this blog post.

Moreover, natural gas is thousands of kilometres away, but biogenic gas can be produced in small tanks for self-supply, e.g. on a farm, or on a large scale in a sewage treatment plant, and existing natural gas pipelines can be used.

It may seem to be all advantages, but this is not the case, which is why CARTIF organised the first meeting of the Community of Practice within the Horizon Europe CRONUS project on 20 March 2024.

The Communities of Practice consist of the grouping of different actors in the biogas sector, such as universities, research centres, producers or distributors, among others, and act as spokespersons for the sector for both citizens and administrations, assessing the strengths and weaknesses, facilities and barriers to the use of biogas in order to make responsible use throughout the value chain.

At this first meeting, three main challenges were addressed:

- Raw materials

- Technology

- Regulations: Logistical, Productive, Social

THE FIRST CHALLENGE, RAW MATERIALS

In the first challenge, the issue of raw materials was addressed. At present, there are no problems in finding them, but there are problems in obtaining supplies, the question is: is this a logistical or quantity limit? In terms of accessibility, it is not as accessible in the mountains as it is on the plateau, and in terms of plant and supplier size.

There is also concern that, in the future, due to the law of supply and demand, both raw materials and transport will reach exorbitant prices. It is necessary to start regulating and organising the market to ensure a supply where the whole value chain benefits.

It is important to consider the methanogenic potential, i.e. how much gas a plant can produce with a given raw material, this determines its viability, therefore the raw materials must meet certain standards and heterogeneity all year round, in order to obtain a constant production, both in quality and quantity.

This leads to the question of the suitability of single or multiple feedstock feeding. In some cases, it is necessary to pre-treat these feedstocks and due to the technical complexity they are not cost-effective, so having flexibility in the use of feedstocks is an advantage.

The most worrying aspect is the injection into the grid. There are problems when it comes to incorporating the gas produced into the existing national distribution network, which in some cases favours the self-consumption of gas, but in others, the waste of this energy source is wasted.

It is a mature technology, but there is still innovation to be done, especially with the bacteria, points of improvement such as new strains are still being discovered, and they make the process and therefore its efficiency is much better known.

In the end, it is an investment, so it is necessary to conscientiously measure the risk and profitability vs. administrative and legal barriers, and although more and more people are opting for it, there would be more if there was a financial push with subsidies, but they would not be the basis of the product.

THE SECOND CHALLENGE, TECHNOLOGY

The second challenge was to know the opinions about the FP5 prototype that is being developed in CARTIF within the CRONUS project. That can be seen in this video.

The expert assistants pointed out that it competes directly with upgrading, so it may not be economically viable on a large scale, but for small plants, it is a good solution, as it does not need to undergo such a large purification process.

On the other hand, it needs a hydrolysis stage, which requires energy, but it is a self-sustainable process, so it is able to be self-sufficient. Technology must favour profitability, as money is always a constraint, both for development and production.

Its strong point was highlighted, which is that it can valorise and reduce the CO2 generated in the AD, obtaining a higher quality biomethane than through traditional processes, especially because cogeneration is more interesting than gas for sale.

As it is the first meeting only the laboratory prototype could be seen, so they perceived that there could be problems in the scaling in the electrodes, as they have to be larger, and there is no microbial electrolysis cell-assisted anaerobic digestion technology (MEC-AD) on the market, but CARTIF already commented that there are more options to integrate MEC-AD in the digester.

It also raised the possibility of problems with having to restart the plant, after a shutdown, which can be slow and complex, but it is a continuous system so it will not be so slow.

The Community is optimistic about CARTIF’s FP5 prototype and is looking forward to seeing its progress in the next calls for proposals.

THE THIRD CHALLENGE, REGULATION: LOGISTIC, PRODUCTIVE, SOCIAL

This challenge is where there was the greatest participation and unanimity. It seems that the Public Administration is not advancing as fast as biogenic gas is. One barrier is the processing time, which can take up to 3 years for project approval, to which environmental authorisations must be added, and the time dedicated to the plant’s engineering project.

This could be favoured with legislation that favours self-consumption, such as premiums or payments for the generation and sale of energy. It would be interesting to map waste production throughout the country.

In the case of Castilla y León, there is the obligation to become an authorised waste manager and limitations on the maximum distance allowed for the transport of digestate, as in the transport of slurry, which shows that the administration is prepared.

But the definition of waste needs to be revised, in order to revalorise by-products for use in anaerobic digestion and also the resulting digestate as it has many potential uses, such as stripping/scrubbing or crystallisation of struvite, which can even be considered as an environmentally friendly product, as fertiliser.

Raw materials, such as slurry, must be used responsibly due to the contamination of aquifers by nitrates, so the use for biogas generation is a solution for this waste, and the resulting digestate could be revalued as fertiliser or as an ingredient for compost.

The growing demand for biogas highlights the need for the modernisation of farms to increase their income from the sale of waste and reduce energy costs by using biogas.

On the other hand, there is a need for the Administration to update its technicians with specific training, since, when evaluating a project, there is no clarity in the criteria, standards and administrative procedures to be applied, and there are differences between technicians.

In short, more support is needed from the Administration, especially with the private companies that control the distribution networks and establish the technical and economic requirements for connection and injection into the network, resulting in abusive technical and economic conditions. The Community of Practice considers this barrier easy to remove.

There is a lack of dissemination and knowledge, which is why citizens associate it with bad smells, noisy lorry movements and a lack of safety, which is why the Community of Practice is doing a good job of disseminating and raising awareness in society of how biogenic gas works and the technology associated with it.

There are both urban and rural barriers, each with its own complexity, in addition to the fact that each Autonomous Community has its regulations in this regard, so each plant in each area must be approached individually, through conferences, citizen participation, a network of interaction with citizens in other areas that already have this technology in place, but above all with transparency.

The reality is that the development of biogenic gas will contribute to rural repopulation, job creation, as well as energy production and the development of the Circular Economy, which is a pending issue in the 2030 agenda.

More information on the CRONUS Project: www.cronushorizon.eu

- Biogenic gas. What do you mean? - 12 April 2024

- Our wonderful guardians and neighbours! - 18 February 2022