When we see a pig, we all tend to think that every part of it can be used: its delicious hams, pork cracklings, chorizo, loins…..including, as the saying goes “even its walk”. However, at CARTIF we know there ir more beyond that: a great variety of by-products and waste generated during the stages prior to the production of all these products.

A similar situation occurs in the sheep sector. Is not only about milk, used for cheese, or meat, such as suckling lamb, but many types of waste also appear throughout the processing stages, such as skins, viscera, or blood, whose treatment entails, apart from its environmental impact, an additional cost for companies.

The cattle sector, in turn, shares common challenges with the previous ones, facing the management of a long list of waste products such as manure, slurry, blood, bones, viscera, and skins, among others.

In the current context where sustainability and circular economy principles are gaining increasing relevance in industrial processes, waste recovery in the meat industry emerges as a key strategy to optimize resources and reduce environmental impact. The activities of the sheep, pig and cattle sectors (which together account for up to 75% of national meat production) offer enormous potential for the full utilization of their waste. In short, we can talk not only about excellent products (milk, cheese, chorizos or hams), but also about good practices by meat companies, closing the production cycle by generating added value through waste recovery. In most cases, these type of waste are managed by external handlers, representing an additional cost for producers. For this reason, all by-products generated in the meat industry require efficient management and call for innovative ideas to turn them into valuable products.

An analysis of the meat production process, according to Nedgia, estimates that a cow produces 50kg of manure per day, which amounts approximately 18,250kg/year (1). When the cow arrives at the slaughterhouse, approximately 40 to 50% of its weight consists of by-products, such as bones, blood, hide, víscera, inedible fat and rumen content, all of which must be properly managed.In addition to this, processing a cow at the slaughterhouse may require between 500 and 1,000 liters of water (2), which subsequently becomes a wastewater stream that also needs to be treated.

Approximately 40 to 50% of a cow weight consists of by-products

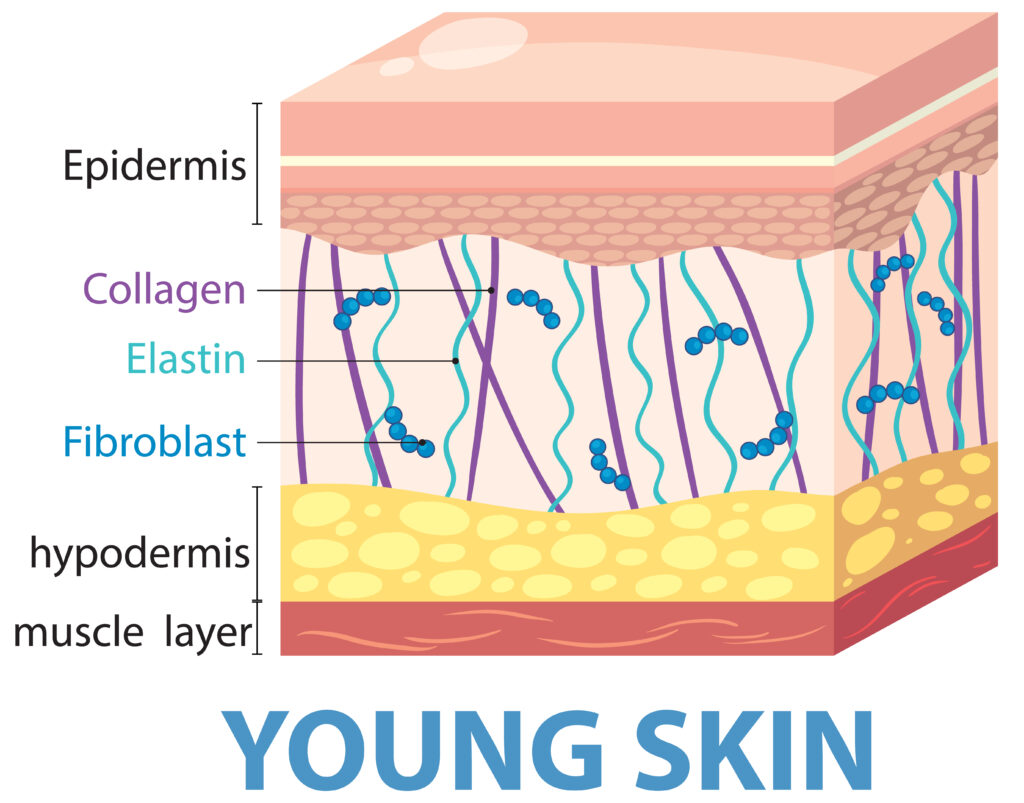

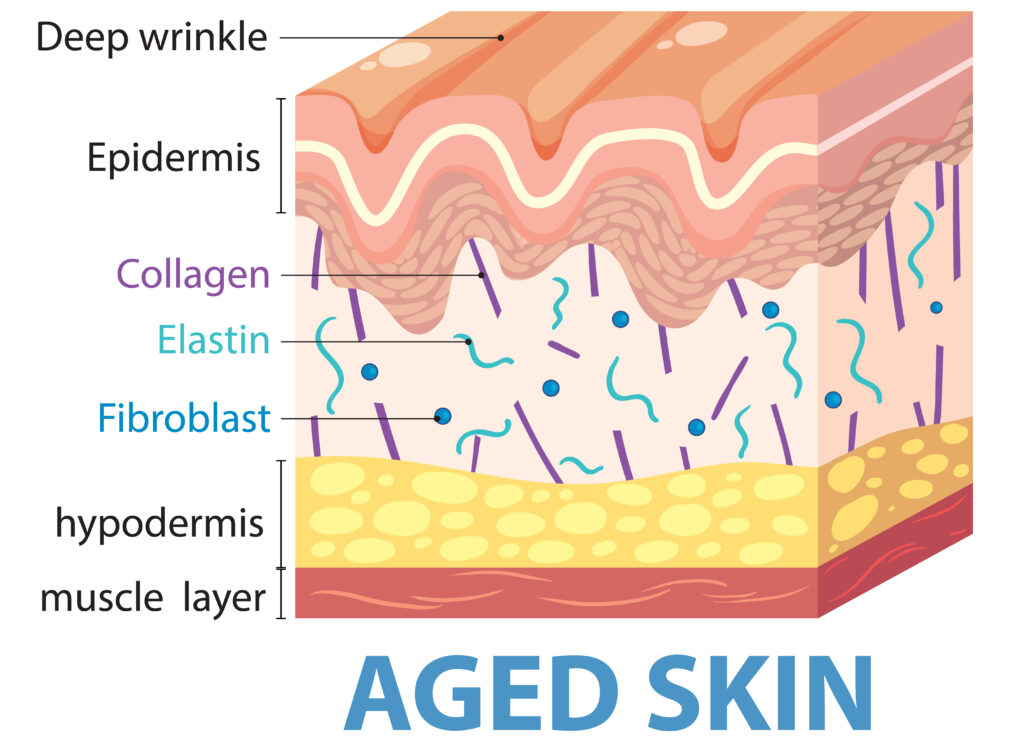

On the other hand, animal hides are already valorized in the textile and footwear industries, but currently, their demand has decreased compared to other fabrics and synthetic leathers. Therefore, efforts are being made to find alternative applications for their utilization. From hides, as well as from bones and cartilage, collagen can be extracted- a product highly sought after by the cosmetics industry due to its many health benefits. Collagen helps create a protective barrier on our skin against external agents, provides firmness and resilience, promotes wound healing, delays the effects of aging and reduce wrinkles, among other benefits (3). Moreover, its use is associated with improvements in the treatment of common diseases such as osteoporosis, arthritis and osteoarhtritis.

According to the Spanish Academy of Nutrition and Dietetics (AEND), from the age of 25, collagen production in a healthy person begins to decline, and it is estimated that by the age of 40, the body produces only half as much collagen as it did during adolescence, with this decrease becoming more pronounced in women after menopause (4). Moreover, one of the reasons why our bones weaken is due to the lack of collagen in the body (5). Many of us remember seeing our grandmothers boiling cow bones to extract collagen, straining the broth for consumption; when refrigerated, this broth would turn into a gelatin rich in collagen. Today, it is possible to replicate this process in the laboratory to obtain concentrated collagen as a nutritional supplement, which requires a purification process that presents various challenges related to obtaining pure collagen, free of fats and other proteins.

Regarding blood, this fraction represents approximately 3–7% of the live weight of the animal, depending on the species, and has traditionally been used in the production of food products (such as blood sausages and others). However, it is also possible to use it for obtaining food colorants or for the extraction of hemoglobin and/or protein that can be incorporated into various products for human or animal consumption. Once the blood has been collected and treated, plasma can be separated from hemoglobin, or the entire fraction can be dried to obtain a protein-rich product.

Another meat by-product is the intestines of animals, which are currently used in the production of sausages such as salchichón, blood sausage, chorizo, and regular sausages, among others. However, the utilization of this fraction (and its associated economic value) remains quite limited. For many years, it has been known that intestines are a rich source of heparin, a highly demanded medication worldwide due to its clinical use as an anticoagulant. The process of obtaining highly pure and stable heparin requires a lengthy preparation and laboratory treatment. Numerous challenges must be overcome during its extraction, such as selecting the most appropriate extraction and purification methods. In addition to using resins, there are other methods that allow heparin to be isolated from other compounds (proteins and other contaminants). Furthermore, it is essential to ensure the stability of the active ingredient, which involves evaluating whether it should be kept in solution or subjected to a drying process.

The valorization of waste from the meat industry is surrounded by many uncertainties, but in this sea of questions, CARTIF emerges, with its researchers studying and developing new processes for the treatment of these by-products, generating new knowledge and finding viable and sustainable technological solutions to these challenges, thereby offering added value to the meat industry.

CARTIF is firmly committed to this line of research, supporting companies in the meat sector in valorizing all their waste, including slurry, for transformation into various products — whether food, energy (such as renewable gases), or even agronomic products (such as organic fertilizers).

As we have seen, it is not only the pig from which everything can be used — even, as the saying goes, “its very walk.”

Co-author.

Pedro Acebes. Researcher at Agrifood and Processes Division

Sources

- https://www.nedgia.es/blog-gas-natural/vacas-contaminacion-metano/

- https://aguasindustriales.es/origen-y-composicion-de-las-aguas-residuales-en-mataderos/

- https://joaquimmunoz.com/alimentos-que-ayudan-a-la-produccion-de-colageno-en-la-piel/

- https://www.academianutricionydietetica.org/nutricion-deportiva/colageno/

- https://www.anamarialajusticiabolivia.com/osteoporosis-y-falta-de-colageno/

- https://www.agrodigital.com/2025/03/06/coste-produccion-leche-pais-vasco-2025/

- Informe trimestral de indicadores económicos marzo 2025. Sector vacuno de carne. Ministerio de Agricultura, pesca y alimentación. Gobierno de España.

- Área de precios. Informe semanal de coyuntura. Precios Coyunturales. Semana 5-2025 del 27 de enero al 2 de febrero. Subsecretaría Subdirección general de análisis, coordinación y estadística.

- Plan territorial de Ordenación de residuos de Tenerife. Residuos de mataderos, decomisos, subproductos cárnicos y animales muestras.

- Universidad Nacional del Nordeste Comunicaciones Científicas y Tecnológicas 2003. Cedrés, José F.

- https://mecanova.eu/desfibrinador-sangre

- https://mecanova.eu/por-que-es-importante-el-tratamiento-de-subproductos-en-un-matadero

- Of the pig, even its walk - 6 June 2025

- Millenary food: superfoods - 22 April 2016

- Gluten-free diet: Is it a new way to lose weight? - 11 March 2016