As you may already know, the increase in greenhouse gas emissions (mainly carbon dioxide and methane) as a consequence of human activity is one of the main reasons behind the faster pace of the climate change in the last decades. And among the wide range of causes, passenger cars are one of the main sources of CO2 emissions, accounting for a 12% of the total emissions (European Commission).

For this reason, the European Union has been adopting increasingly stricter measures to regulate the levels of emissions. In 2015, a limit of 130 grams CO2/km was set. Moreover, by 2021 a more ambitious target is planned to be fixed at 95 grams CO2/km.

In this context, car manufacturers have been forced to reduce fuel consumption (or increasing the autonomy in electric vehicles) and emissions in his petrol and diesel-fuelled models. How can automakers do that? Besides designing more efficient engines, the main strategy is lightweighting. This technique consists of reducing the weight of the car by replacing the heavier materials (i.e. steel) by lighter ones such as plastic or composites.

However, currently the mismanagement and misuse of plastics rather than the material itself is one of the top environmental issues, since 8 million tons out of the 300 million tons of plastic which are annually produced end up in the ocean (According to data from the International Union for Conservation of Nature). So seems that increasing the use of plastics in cars does not look like and ideal solution, right? Well, how about using an alternative material with similar of even better performance than conventional plastics and reduced environmental footprint? It doesn’t seem an easy task, although bioplastics may be part of the answer.

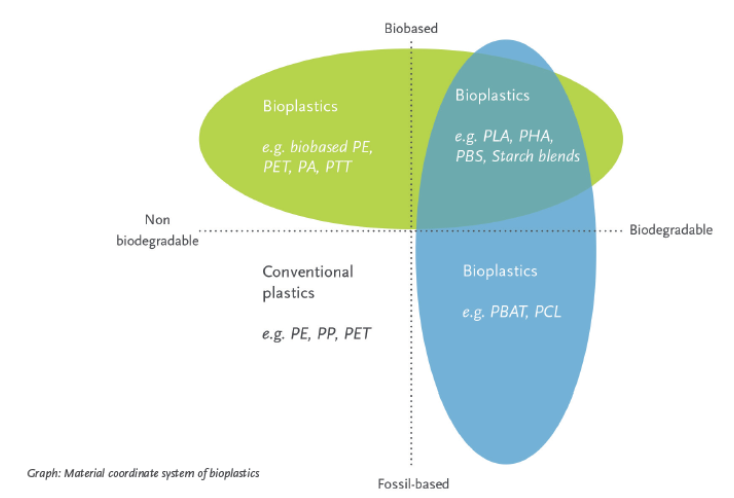

What are bioplastics, and why they seem to be so trendy nowadays? According to European Bioplastics, it’s a heterogeneous set of materials with different properties and applications which can be biobased, biodegradable or both.

In other words, since they are biobased, their use potentially reduce the consumption of fossil fuels while their biodegradability widens the possibilities of treatment at the end-of-life stage. As a result, these materials could achieve the desired combination of performance and sustainability.

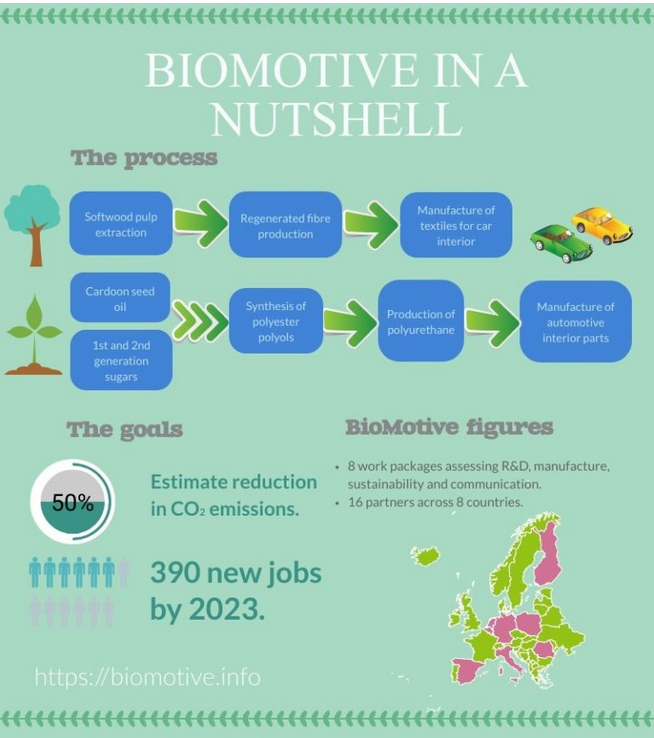

This is what the BIOMOTIVE project is all about. It tries to develop materials (textile fibres, foams made of polyurethane for automotive seating and other polyurethane-based parts for the interior of cars) from biobased sources which combine good technical properties with reduced environmental impact. Starting from renewable raw materials such as forest biomass and vegetable oils not in competition with the food chain, it is expected to produce at industrial scale products with up to 80% biobased content.

The project has received funding under the European Union’s Horizon 2020 Research and Innovation Programme and gathers European private companies and institutions sharing the ideal of reducing the impact of the industry paving the way towards a more sustainable economy.

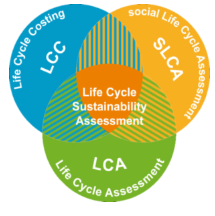

The role of CARTIF in the project is to perform the sustainability assessment of the final products, since the prefix “bio” does not necessarily mean that a product is better for the environment than its fossil-based counterpart. To determine that on a scientific basis, it is important to evaluate the impacts of the product along its whole life cycle (that is, from the extraction of raw materials to the end of life) considering not only the environmental impacts, but also social and economic aspects.

So the next time you are holding a plastic object, before throwing it away, it is worth considering from where it came and where will it go.

- Going green on your car (in a good way) - 3 October 2019