The future of construction is printed in 3D

3D printing is here to stay. When a new technology is so widespread that no longer catches the attention it is that its implementation is complete. More and more people have a plastic 3D printer at home and many of us know someone who has bought one or it has been built by pieces. It was only a matter of time before this technology would give the jump to other sectors. Although the construction sector usually adopts this type of technological developments rather late, in this case there are already several projects trying to bring the additive manufacturing (as is also known 3D printing) to construction.

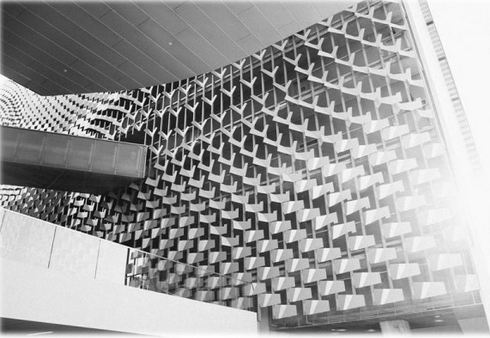

What is wanted, among other things, it is to face the new architectural designs that are increasingly complex, industrialize certain construction processes which, today, are almost artisanal and improve sustainability using recycled materials for printing.

Such systems pose major challenges such as the development of new building materials that allow their proper implementation. Usually, the addition of other materials or compounds that improve the properties (or achieve the desired properties) in setting times, strength and insulation is used.

One of the first projects in relation to additive manufacturing in construction is called “Contour Crafting“, led by Dr. Behrokh Khoshnevis of the University of Southern California. And now there are many research centres and universities focused on these issues as AMRG University of Loughborough considered a world reference or IAAC in Spain.

They have also appeared commercial developments such as the case of a Chinese company that manufactured homes, offices and entire buildings using these techniques. The specific case of this company seems to respond to marketing strategies (which seems to be taking effect) because a good position in these technologies can open important markets.

In any case, there are many interesting initiatives such as WASP, an Italian project for sustainable buildings in disadvantaged areas, the construction of a steel bridge in Amsterdam, or NASA contest for construction of buildings on the moon or Mars using these techniques, the winner of which proposed the use of ice as raw material.

In the light of these developments it is easy to see that the additive manufacturing construction offers some advantages hard to match with other methods such as complexity in designs that can be obtained, the accuracy and repeatability of certain construction procedures. It is undeniable that industrialization is increasingly integrated into many building processes and 3D printing sure to have your niche in the construction sector.

As always with new technologies, certain optimistic sectors are saying that the additive manufacturing will be the majority system used in all industries but certainly there are currently no universal manufacturing technologies (beyond certain methods such as mass production). The current manufacturing processes are highly specialized and uses the most appropriate technologies in each case it seems complicated than a single technology is able to replace almost all existing. Therefore, and being realistic, we must find the most suitable application field for 3D printing in construction.

In this regard, CARTIF participates in a major national research project related to 3D printing in construction. This project focuses on the application of 3D printing technologies in construction in those areas where it is considered that can be especially useful: the manufacture of prefabricated modules and rehabilitation of facades. It does not seek a universal technology to serve in all areas of construction, but to reach the market with a product that offers a viable alternative to other existing technologies (i.e. realistic and sustainable applications). And without forgetting that all progress made in this field (whether by R & D or marketing strategies) will impact in the future, for the benefit of the whole society because what it is pursued, is to build better, faster, cheaper and in a more sustainable way.