Know your enemy

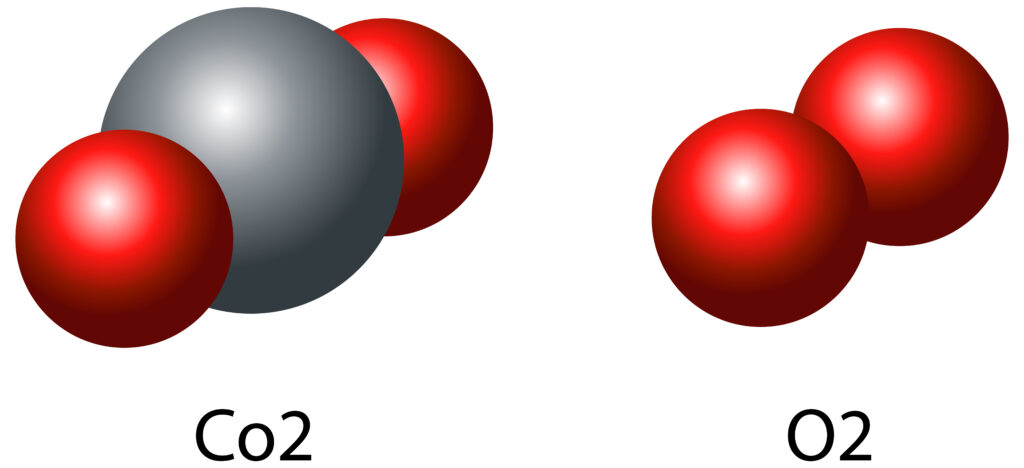

If one were to see (and smell) the gases produced by combustion and anaerobic digestion, one would not find many similarities apart from the state of the matter in which they are found. In fact, both have a common component that is odorless, colorless, and tasteless: carbon dioxide, composed of one carbon atom and two oxygen atoms (CO2). It is a natural component of the atmosphere, with an average concentration of around 420 mg/L, and plays an essential role in biological processes such as photosynthesis and respiration.

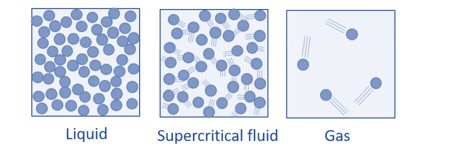

From a physical-chemical point of view, CO₂ has versatile properties. At ambient temperature and pressure, it is in a gaseous state, but it can be liquefied at pressures above 15 bar at -20 °C. Carbon dioxide (CO₂) has a peculiar characteristic: at normal atmospheric pressures, it can change directly from a gaseous state to a solid state without passing through a liquid state. This process is known as reverse sublimation. Thanks to this property, CO₂ is used in the form of “dry ice,” which has a temperature of -78.5 °C, and is widely used in the refrigeration and transport of temperature-sensitive products.

These phase transitions of CO₂ are exploited in various industries, such as food and pharmaceuticals, due to their efficiency and safety in product preservation.

In industrial terms, CO₂ is widely used in processes such as beverage carbonation, atmosphere inerting, welding, fire extinguishing, and as a fluid in emerging technologies such as carbon capture and storage (CCS). It is also a key gas in the production of biofuels and power generation, where it is used in a supercritical state (above 31°C and 74 bar) thanks to its unique solubility and density properties.

However, CO2 is also a greenhouse gas with a high climate impact, which is why its proper management is essential. Innovations in its capture, reuse, and recovery are opening up new opportunities to reduce emissions, convert it into useful products, and move towards a more sustainable and circular economy.

That is why at CARTIF we believe that capturing CO2 at source is of the utmost importance. In this case, we have focused both on CO2 from biogas formation and CO2 from biomass combustion.

In biogas formation, CO2 is produced through anaerobic processes, where microorganisms break down organic matter in the absence of oxygen. In this anaerobic digestion, bacteria transform polysaccharides and fats into a mixture of methane (CH4) and carbon dioxide. Typical biogas contains between 30-45% CO2, which is not only an inevitable by-product, but also influences the calorific value of biogas because it is an energetically inert gas, i.e., it does not participate in combustion and therefore does not contribute energy. The higher the proportion of CO₂ in the mixture, the lower the concentration of CH₄, which is the combustible component responsible for the energy content. A typical biogas with 60-70% methane has a calorific value of 20-25 MJ/m³, whereas if the CO₂ content increases and methane decreases, this value can be significantly reduced, affecting efficiency in boilers, engines, and turbines.

“A typical biogas with 60-70% methane has a calorific value of 20-25 MJ/m3”

In biomass combustion, CO2 is generated from the oxidation of carbon contained in organic materials such as agricultural and forestry waste or pellets. During the reaction, the carbon (C) present in the biomass combines with oxygen (O2) in the air, releasing energy in the form of heat and producing carbon dioxide (CO2) and water vapor (H2O). This process is rapid and occurs at high temperatures, forming the basis of technologies such as boilers and cogeneration plants. In biomass combustion, the typical concentration of CO2 in the combustion gases is usually between 3% and 15% by volume, depending on the type of biomass, the amount of oxygen available, and the efficiency of the process. This value is relatively low because, in addition to CO2, the gases contain a large amount of nitrogen (N2) from the combustion air, as well as water vapor, residual oxygen, and small traces of carbon monoxide (CO) and other compounds.

Welcome to the solution, we have membranes and contactors

The solution proposed by CARTIF consists of using a membrane contactor system, which can separate CO2 from a stream of multiple gases, obtaining a high-purity CO2 output.

A membrane contactor is an advanced technology used to separate and purify gases, in this case, for the capture and concentration of CO2 from gas streams. Its operation is based on the principle of mass transfer through a hydrophobic membrane, which acts as a physical barrier between the gas stream and an absorbent liquid that reacts selectively with CO2.

The system consists of a module with thousands of hollow fibers made of polymeric material. The gas containing CO₂ mixed with other components circulates on one side of the membrane (usually the inside of the fibers), while the absorbent liquid flows in countercurrent on the opposite side. Thanks to the hydrophobic nature of the membrane, it prevents the passage of liquid but allows CO₂ to diffuse through its pores, driven by a partial pressure gradient. Once the CO₂ passes through the membrane, it is captured by the liquid absorbent, which in our case can vary between distilled water or a NaOH solution. This process offers high selectivity, as other gases such as methane do not pass through the pores of the membrane and remain in the gas stream, thus obtaining a purified gas with a lower concentration of CO2.

Subsequently, the CO2-saturated liquid is sent to a regeneration stage, where, through a drop in pressure, the pure CO2 is released, while the absorbent liquid is recycled to return to the first contactor. The recovered CO2 can be stored, compressed, or reused in industrial processes such as carbonation, inerting, or synthetic fuel production.

And the CO2 obtained?

The membrane contactor system for extracting CO2 from gas streams has been tested at the Center with good separation yields, so it has now been decided to add a CO2 compression system to our pilot plant to store it in bottles in gaseous form, so that it can be used in different industrial applications (carbonation of beverages, microalgae growth, synthesis of other molecules, etc.).

A CO2 compressor works by increasing the pressure of the gas through the progressive reduction of its volume via one or more compression stages. At each stage, a piston reduces the space occupied by the CO2, raising its pressure and temperature. To prevent overheating, the gas is usually cooled between stages using heat exchangers. This process allows the CO2 to be brought from conditions close to atmospheric pressure to storage pressures in order to prevent it from liquefying.

Therefore, the system is designed to maintain temperature and pressure within safe ranges, ensuring that the CO2 remains in the gaseous phase throughout the process. This allows for more stable, safe, and economical operation, especially in pilot projects or CO2 reuse projects, where simplicity and reliability are key.

Conclusions: from climate waste to strategic waste

Carbon dioxide (CO₂) is one of the main greenhouse gases, whose atmospheric concentration has increased significantly due to human activities such as the burning of fossil fuels and certain industrial processes. Reducing these emissions is key to mitigating climate change and moving towards a more sustainable production model. However, CO₂ should not be seen solely as a waste product, but as a valuable resource that can be captured, purified, and reused in different sectors within a circular economy.

In this context, membrane contactor technology is an innovative and efficient solution for CO₂ purification. These systems allow carbon dioxide to be separated from gas mixtures such as biogas or combustion gases through a physical-chemical process based on hydrophobic membranes and a selective absorbent liquid. Their modular design offers a large contact surface in a small space, improving efficiency and reducing energy consumption compared to traditional methods. Thanks to this technique, it is possible to obtain high-purity CO₂ while other gases, such as methane, remain free of contaminants and ready for use.

Once purified, CO2 must be stored safely. To do this, compression and storage systems in gas cylinders are used, designed to keep the CO2 in a gaseous state, preventing it from liquefying. This involves compressing it to controlled pressures, generally between 15 and 20 bar, using multi-stage compressors that ensure the stability and safety of the process. The compressed gas is stored in cylinder racks that allow for its transport and subsequent use. This step is essential not only to ensure the integrity of the equipment, but also to comply with industrial safety regulations.

Captured and stored CO2 can have multiple industrial applications, from beverage carbonation and food preservation to use in welding processes, fire extinguishing, or as a raw material in the production of synthetic fuels and chemical products. In this way, what was once considered waste becomes a value-added input. This approach is a clear example of the circular economy, where production cycles are closed, emissions are reduced, and resource efficiency is promoted.

In short, the integration of capture technologies such as membrane contactors, together with compression and storage systems, not only reduces the environmental impact of CO₂, but also transforms it into an economic and technological opportunity, driving the transition towards cleaner, more resilient, and sustainable industries.